- Overview

- Related Products

Introducing, Weiyue's OEM Factory Custom Made Hot Forging Services for Machinery Parts!

Weiyue is a leading provider of high-quality hot forging services for all your machinery part needs. Our OEM factory is equipped with state-of-the-art technology and experienced professionals who are dedicated to delivering top-notch products to our customers.

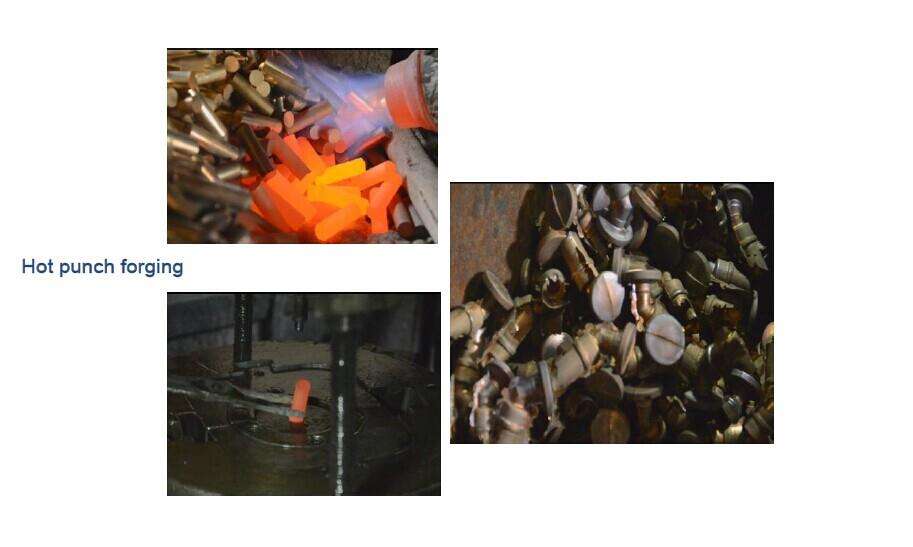

When it comes to hot forging, we utilize the process of shaping metal while it is hot using compressive force. This results in machinery parts that are incredibly strong and durable, making them perfect for even the most demanding applications.

Our custom-made hot forging services allow us to create machinery parts to your exact specifications. Whether you need gears, shafts, brackets, or any other component, we can produce it with precision and expertise.

At Weiyue, we understand the importance of quality and reliability. That's why we put all of our products through rigorous testing to ensure they meet the highest standards. Our hot forged machinery parts are built to last, providing you with superior performance and longevity.

In addition to our exceptional quality, Weiyue also offers competitive pricing and fast turnaround times. We understand the importance of getting your machinery parts quickly, so we work efficiently to ensure prompt delivery.

Whether you are in need of custom machinery parts for a new project or replacement parts for existing equipment, Weiyue's OEM Factory Custom Made Hot Forging Services are the ideal solution. Trust in our expertise and dedication to provide you with the best products for your machinery needs.

Don't settle for subpar machinery parts – choose Weiyue for top-quality hot forged products that will exceed your expectations. Contact us today to learn more about our hot forging services and how we can help you with your machinery part needs

Products introduce

OEM Factory Custom Made Hot Forging Services for Machinery Parts

We are the factory provide custom made parts with hot forging, stamping and cnc machining processes

Forging machine from 63 tons to 500 tons can produce parts from 20g to 2500g

Forging tolerance +/-0.05mm

Over 100 sets of cnc lathe with MAX OD 120mm, Min tolerance +/-0.01mm

OEM/ODM Service |

According to customers prints, drawings, specifications or samples |

Production range |

Auto parts, industrial metal parts, machine fitting and hardware parts |

Available materials |

Steel alloy, brass, aluminum/zinc alloy, iron and stainless steel |

Manufacturing process |

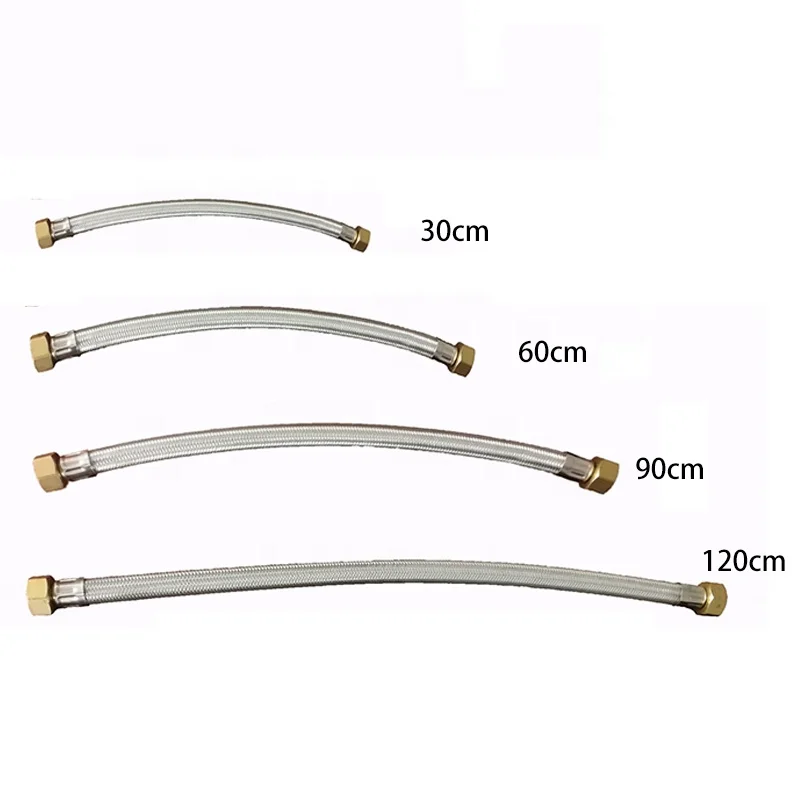

· Hot forging + machining · Warm/cold compressing + machining · Sheet stamping + machining · Bar stock + cnc machining · Braiding - stainless steel wire |

Available production processes |

Annealing, heat treatment, sand-blasting, surface plating, polish, QC testing and packing |

Available finishes |

Fine polished, chrome, zinc, nickel plating, anodize with all kinds of customized colors, etc |

Target customer |

Direct manufacturers, EAU purchase amount from $0.2 million to 2 million |

Delivery time |

2-6 weeks for samples, 4-8 weeks for mass-production delivery |

Steel forging parts view

Brass forging parts view

Other forging parts view

Founded in 2001, Cixi Weiyue Metal Product Co., Ltd. is a specialized provider of metal forging, machining, stamping customized parts and Stainless Steel Braided Hose. We have a complete in-house manufacturing system - from products design, making, testing, to parts processing and assembly. With over 15 years of export experience, we have established a long-term cooperation relationship with many customers in Europe, America, Middle East and South-east Asia and all over the world

All our products are manufactured under Precision manufacturing, which have five floors of 4810 square meters. Owning various types of precision automatic equipments: 120 sets of CNC Lathe, CNC machining centers, forging and Stamping Machines, thread rolling machines and other processing machines. those have a monthly capacity of 3,000,000 units, to match your volume orders. There are also lots of testing equipment for quality assurance. Such as: three dimensional, optical Projector, Surfagauge, Sclerometer, Tension tester, etc. Quality Control All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard. Available materials: brass, mild steel, steel alloy, stainless steel and iron, aluminum, zinc; Available surface finish: fine polish, electrolyte-polish, chrome, zinc plating, nickel plating, aluminum oxidation. Available processes: metal processing includes machining, stamping, die-cast and hot-press, expert plastic injection, and surface plating. OEM orders are welcome Contact us NOW If you have new project please send your 2D or 3D drawing(STP, IGS) file to us, we will be quote to you in 24hours

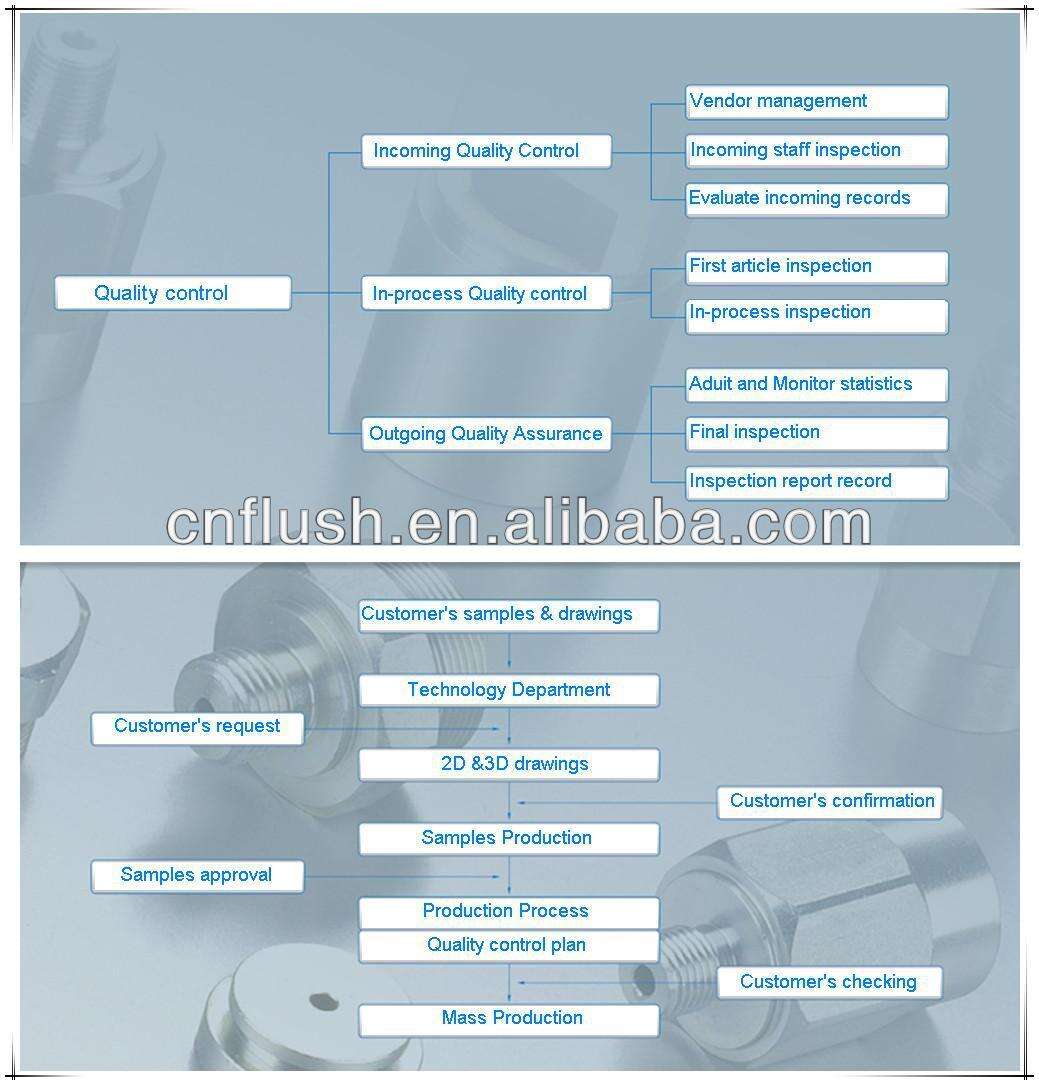

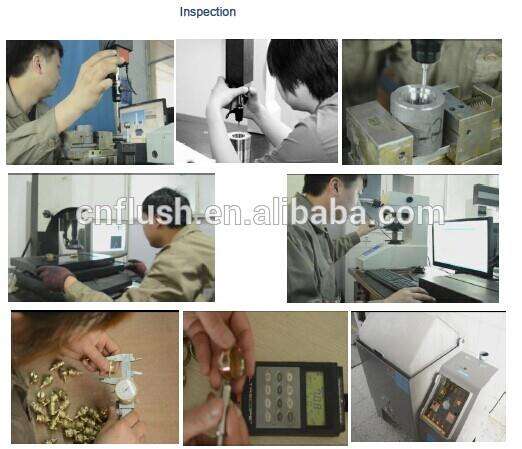

Quality Control

All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard, to make sure that only quality parts leave our plant

Production Equipment and ability

PRODUCTION EQUIPMENT |

TYPE |

QTY |

SIZE |

TOLERANCE |

CNC Lathe |

turning |

120 sets |

MAX OD 120mm |

Min +/-0.01mm |

Punch |

hot forging |

3 sets |

60-80 tons |

+/-0.05mm |

cold stamping |

29 sets |

15-100 tons |

+/-0.05mm |

|

Hydraulice press machine |

hot&cold press |

2 sets |

315-500 tons |

+/-0.02mm |

Rolling machine |

Threading and diamond rolling |

2sets |

Max OD 25mm |

+/-0.05mm |

Factory Production work shop and capacity

Precision forging, that include puch hot forging and press forging, have 3 sets of 63 tons to 125 tons forging machine, and 2 sets of 300 tons and 500 tons of hydraulic machine for cold or warm form press forging process. Available to produce the parts from 20g to 2500g.

Precision CNC lathe machining workshop, have 120 sets of CNC lathe, available to contrail the MIN tolerance at +/-0.01mm.

Metal stamping workshop

have 17 sets of stamping machine from 6.3 tons to 125 tons, those contain 2 sets of 60 tons precision punching machine for stamping

Inspection, assembly and packing workshop

Other forging parts view part show

Contact us NOW

We are always try our best to provide you premium quality products with competitive price. Should any requirement, please do not hesitate to contact us

Business Types

OEM Manufacturer

Exporter

Markets

World Wide

FAQ:

Q1. What are your main products

A1:Our main products are brass forging parts and machined parts

Q2. How to ensure that every process's quality

A2:Every process will be checked by our quality inspection department which insures every product's quality. In the production of products, we will personally go to the factory to check the quality of products

Q3. How long is your delivery time

A3:Our delivery time is generally 30 to 45 days. Or according to the quantity

Q4. What is your payment method

A4:30% value of T/T in advance and other 70% balance on B/L copy

For small order less than 1000USD, would suggest you pay 100% in advance to reduce the bank charges

Q5. Can you provide a sample

A5:Sure, Our sample is provided after receiving the tooling cost and courier fees.