- Overview

- Related Products

The Weiyue Zinc Alloy Garden Water Hose Valve Connector is a reliable and handy tool designed to make your gardening and outdoor watering tasks easier. Made from high-quality zinc alloy, this connector is built to last and withstand the wear and tear of everyday use. It is perfect for connecting water hoses quickly and securely, ensuring you have a steady and leak-free water flow whenever you need it

This valve connector is designed for easy attachment to your garden hose, making it simple to connect or disconnect without the use of extra tools. The zinc alloy material not only offers great durability but also resists rust and corrosion, which is important when working with water. This means the connector will stay strong and functional even after long exposure to moisture and outdoor elements

One of the key features of the Weiyue garden hose valve connector is its built-in shut-off valve. This allows you to control the water flow directly at the connection point without needing to go back to the main water source. You can quickly open or close the valve, making watering more convenient and efficient. Whether you want to stop watering to adjust your hose or change attachments, this valve connector saves you time and effort

The connector fits most standard water hoses, making it a versatile addition to your gardening tools. It is designed to provide a tight and secure fit, preventing water leaks that can waste water and create messes. With this connector, you can be confident that your watering system is working smoothly, which helps your garden stay healthy and hydrated

Installing the Weiyue Zinc Alloy Garden Water Hose Valve Connector is simple and straightforward. Just screw it onto your garden hose or watering device and tighten it by hand. There’s no need for complicated assembly or special tools. Its solid construction and user-friendly design make it suitable for both beginners and experienced gardeners

The Weiyue Zinc Alloy Garden Water Hose Valve Connector is an essential accessory for anyone who uses water hoses in their yard or garden. It combines durability, convenience, and ease of use into one compact device. With this connector, you get a dependable way to connect and control your garden hoses, making your outdoor watering routine smoother and more effective. If you want a quality product that lasts and works well, the Weiyue valve connector is a smart choice

Features:

Features:

1. W8021: 2-way hose shut-off valve, Zinc Alloy Garden Water Hose Valve Connector Use to Connect Water Hose

2. Material: zinc die-casted with chromate finish

3. 3/4" male thread with shut-off valve

4. thread: 3/4" male and female

Zinc alloy Garden water valve show

Brass garden water hose valve

Cixi Weiyue Metal Product Co., Ltd formerly known as Cixi Fule Flooding Equipment Co., Ltd

Set up in the year of 2001, is one of the manufacturing factory main provide customization metal die-casting, forging, cold or warm form pressing, stamping and precision CNC lathe machining service, We have a complete in-house manufacturing system-from products design, making, testing to parts mass-production

Our factory have been approved by ISO9001:2008 supervisory system, all our workshop and products are manufactured under it. Main processes workshop include precision forging and stamping workshop, cold/ward forming press workshop, CNC lathe machining workshop, and inspection and packing workshop

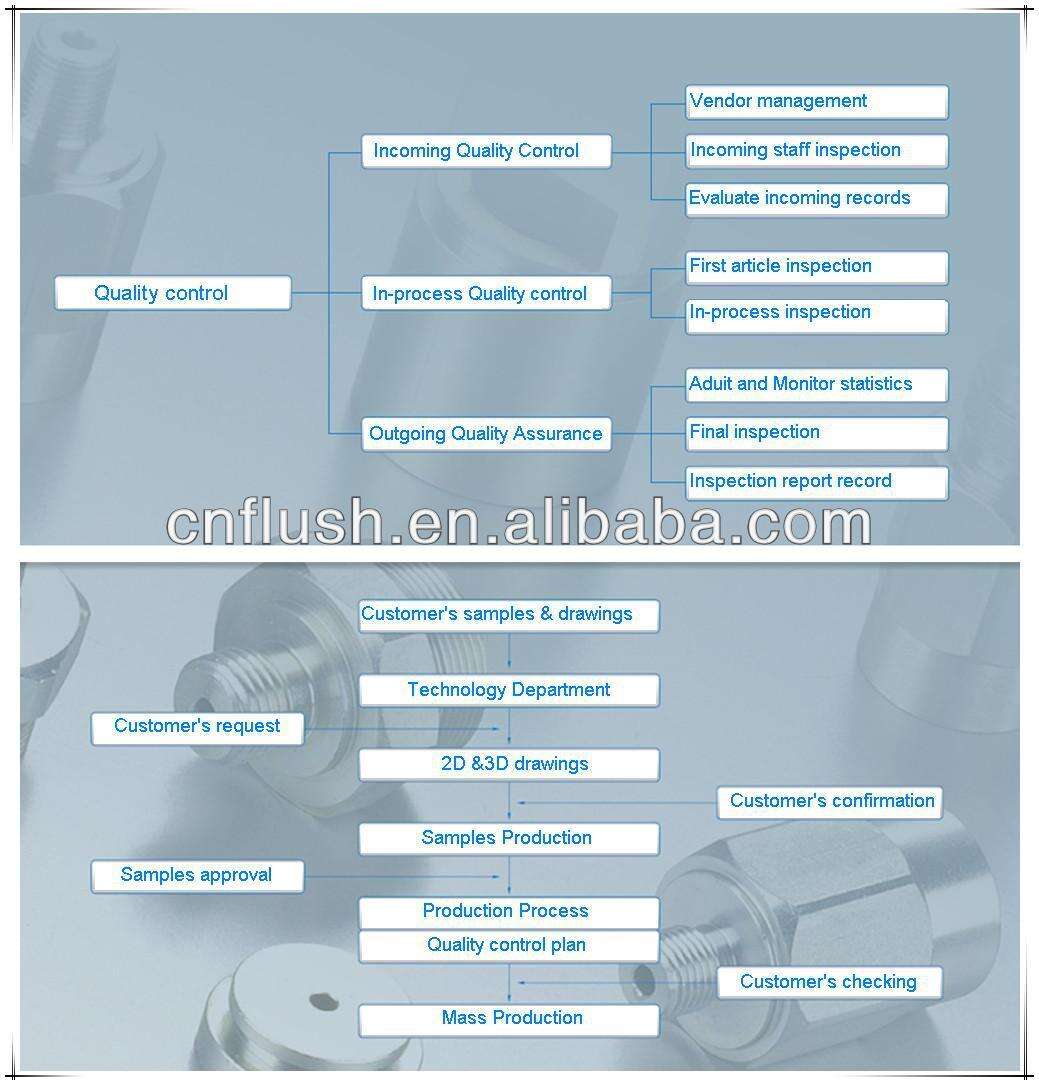

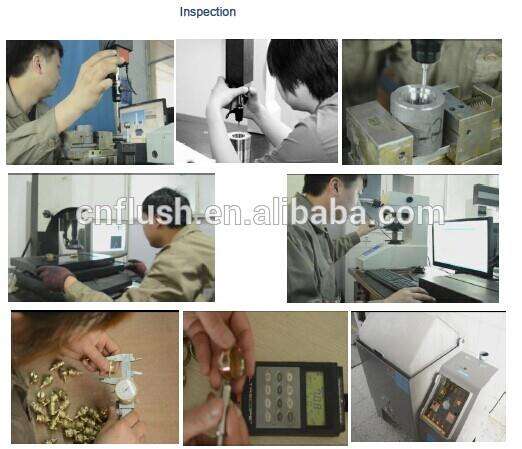

Quality Control

All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard, to make sure that only quality parts leave our plant

Production Equipment and ability

PRODUCTION EQUIPMENT |

TYPE |

QTY |

SIZE |

TOLERANCE |

CNC Lathe |

Turning |

120 sets |

MAX OD 120mm |

Min +/-0.01mm |

Punch |

Hot forging |

3 sets |

60-80 tons |

+/-0.05mm |

Cold stamping |

29 sets |

15-100 tons |

+/-0.05mm |

|

Hydraulice press machine |

Hot&cold press |

2 sets |

315-500 tons |

+/-0.02mm |

Rolling machine |

Threading and diamond rolling |

2sets |

Max OD 25mm |

+/-0.05mm |

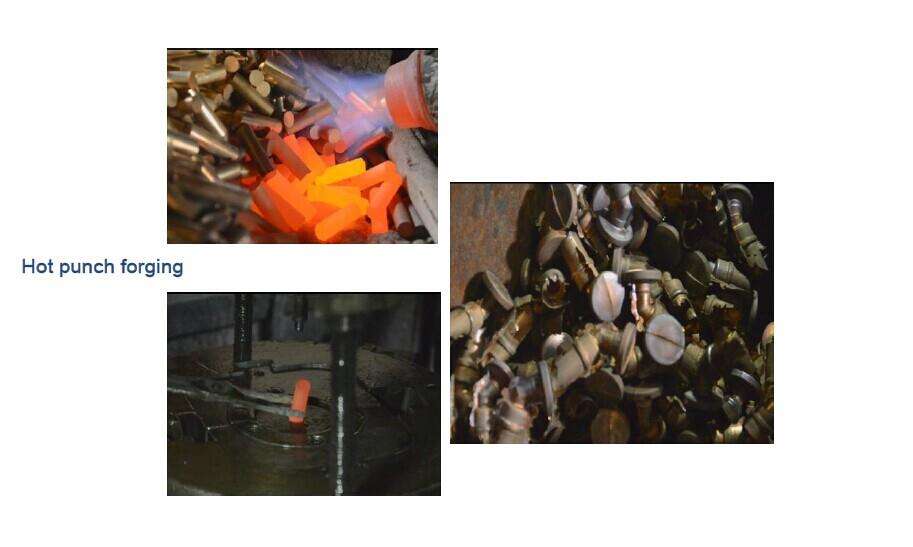

Factory Production work shop and capacity

Precision forging, that include puch hot forging and press forging, have 3 sets of 63 tons to 125 tons forging machine, and 2 sets of 300 tons and 500 tons of hydraulic machine for cold or warm form press forging process. Available to produce the parts from 20g to 2500g

Precision CNC lathe machining workshop, have 120 sets of CNC lathe, available to contrail the MIN tolerance at +/-0.01mm.

Metal stamping workshop

Have 17 sets of stamping machine from 6.3 tons to 125 tons, those contain 2 sets of 60 tons precision punching machine for stamping

Inspection, assembly and packing workshop.

Other Zinc alloy Garden water valve

Contact us NOW

We are always try our best to provide you premium quality products with competitive price. Should any requirement, please do not hesitate to contact us

Business Types

OEM Manufacturer

Exporter

Markets

World Wide

FAQ:

Q1. What is your main products

A1:Our main products are hot or cold forging parts, stamping parts and cnc machining parts

Q2. How to ensure that every process's quality

A2:Every process will be checked by our quality inspection department which insures every product's quality

Q3. How long is your delivery time

A3:Our delivery time is generally 35 to 45 days. Or according to the quantity

Q4. What is your payment method

A4:30% value of T/T in advance and other 70% balance on B/L copy

For small order less than 1000USD, would suggest you pay 100% in advance to reduce the bank charges

Q5. Can you provide a sample

A5:Sure, Our sample is provided after receiving the tooling cost and courier fees