ماشینکاری CNC سفارشی از قطعات صامتکننده فولادی فلزی آلومینیومی آهنی کاربرد ماشینآلات - فرآیند جوشکاری گرم و جوشکاری قالب

- بررسی اجمالی

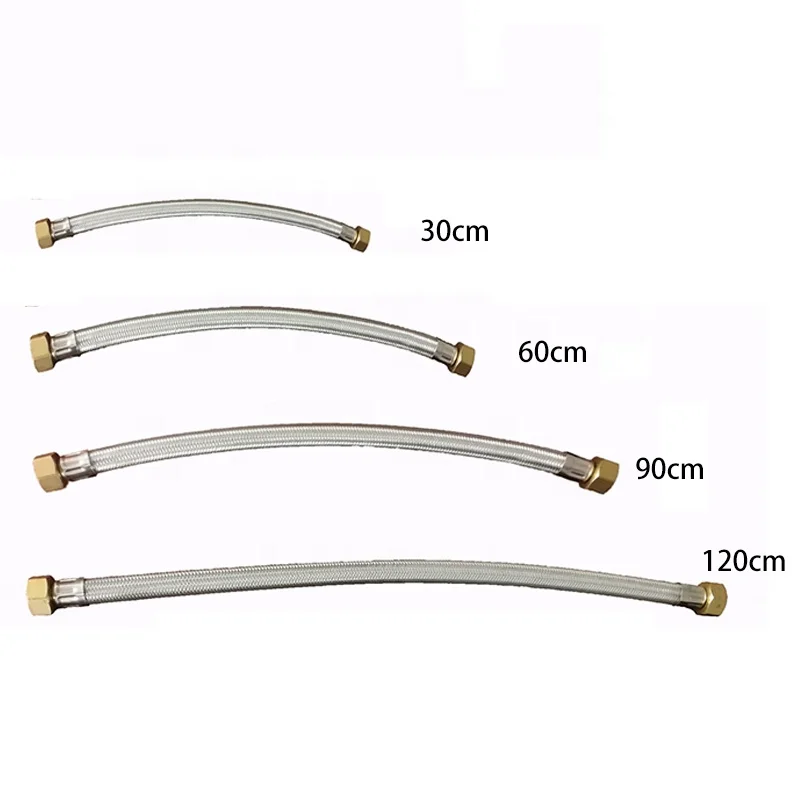

- محصولات مرتبط

معرفی خدمات نوآورانه ماشینکاری CNC سفارشی وییو برای قطعات مخفف فورج شده از جنس فولاد، فلز، آلومینیوم و آهن. ماشینآلات پیشرفته و فناوریهای بهروز ما امکان دقت و ظرافت در تولید قطعات با کیفیت بالا را برای کاربردهای مختلف ماشینآلات فراهم میکنند.

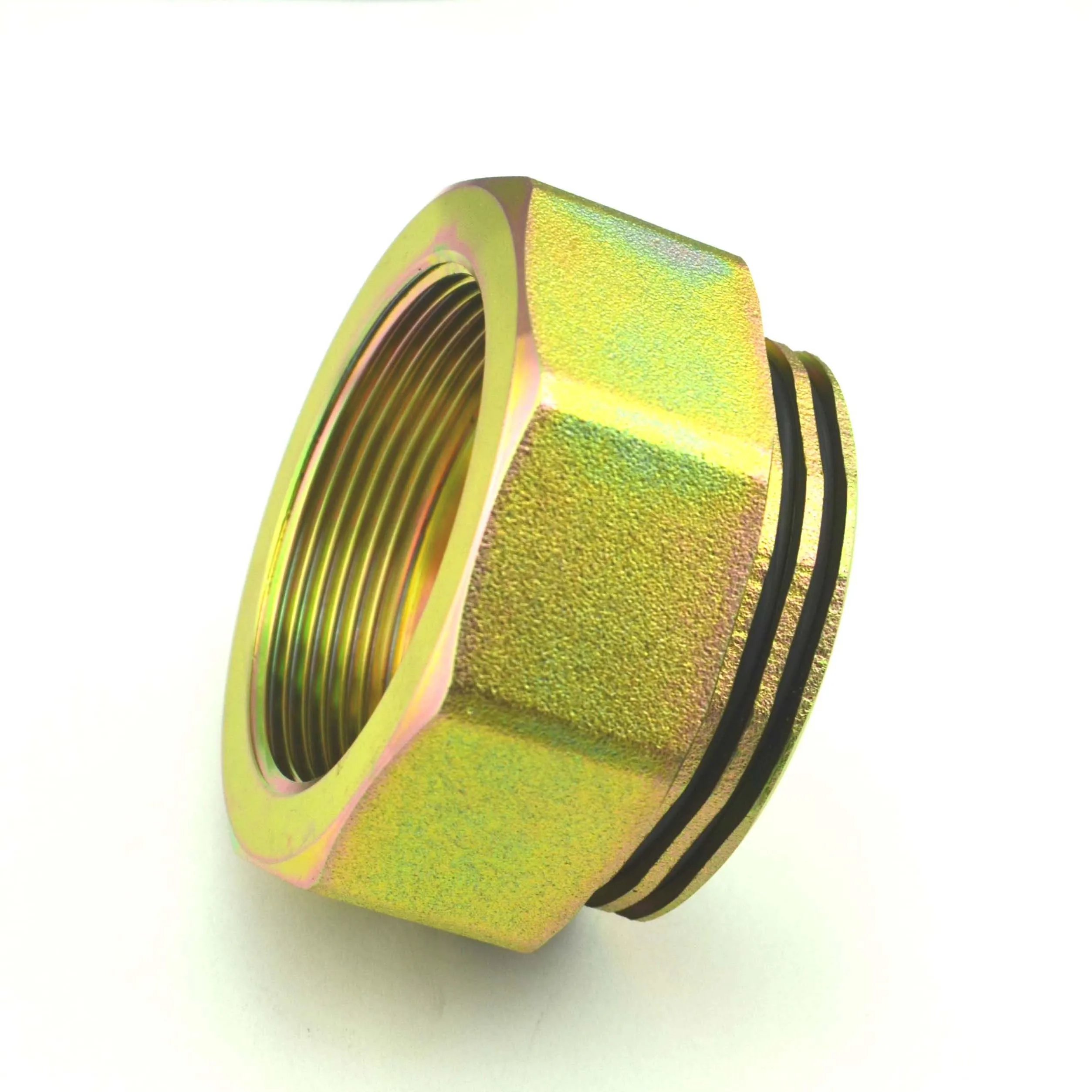

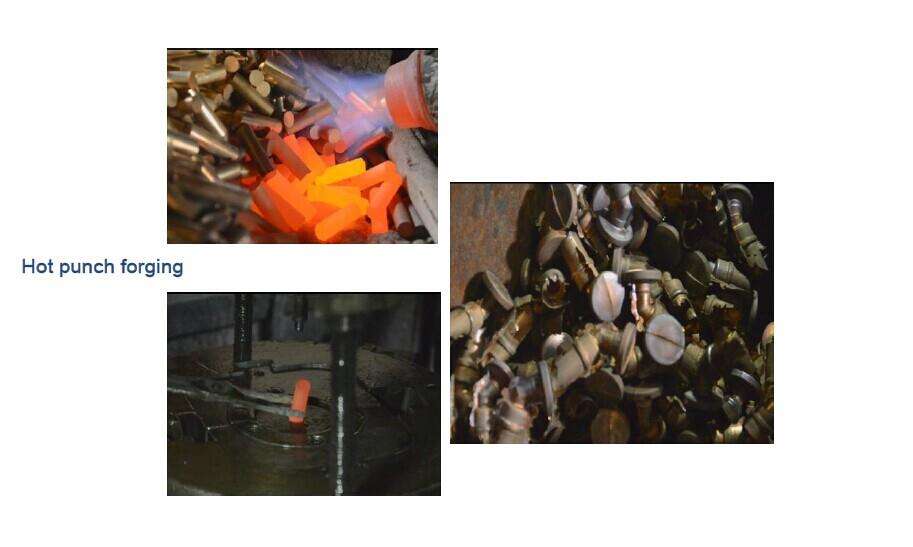

فرآیند ماشینکاری CNC سفارشی ما با استفاده از تکنیکهای ریختهگری تحت فشار و آهنگری گرم پیشرفته، قطعات مخففی با دوام و قابل اطمینان تولید میکند که دقیقاً با مشخصات مشتریان ما مطابقت دارند. چه قطعاتی برای کاربردهای خودرویی، صنعتی یا سایر ماشینآلات نیاز داشته باشید، وییو دارای تخصص و توانایی لازم برای ارائه راهحلهای سفارشی متناسب با نیازهای منحصربهفرد شماست.

تیم متخصص ما از مهندسان و تکنسینان با تجربه، بهصورت نزدیک با مشتریان همکاری میکنند تا نیازهای خاص آنها را درک کنند و در مورد روشهای تولید کارآمد و مقرونبهصرفه توصیههای لازم را ارائه دهند. از مرحله اولیه طراحی تا تولید نهایی، ما مطمئن میشویم که هر پروژه با دقت و کیفیت بالا به اتمام برسد.

در شرکت وییو، ما تعهد داریم تا محصولاتی عالی تحویل دهیم که انتظارات مشتریان ما را فراتر ببرند. تعهد ما به نوآوری و بهبود مستمر، ما را به سمت گسترش مرزهای ممکن در زمینه ماشینکاری CNC سوق میدهد. با سرمایهگذاری در فناوریها و تجهیزات جدید، قادریم حتی پیچیدهترین وظایف ماشینکاری را با دقت و کارایی انجام دهیم.

در کنار خدمات ماشینکاری CNC سفارشی، وییو همچنین خدمات ارزشافزودهای مانند تکمیل سطح، بازرسی کیفیت و بستهبندی سفارشی ارائه میدهد. ما در وییو تلاش میکنیم تا تجربهای یکپارچه و بدون دغدغه برای مشتریان خود فراهم کنیم، از مشورت اولیه تا تحویل نهایی.

چه به قطعات ساکنکننده سفارشی برای یک کاربرد ماشینآلات خاص نیاز داشته باشید و چه قصد بهبود عملکرد تجهیزات موجود را داشته باشید، وییو دارای تخصص و منابع لازم جهت کمک به دستیابی به اهداف شماست. امروز با ما تماس بگیرید تا اطلاعات بیشتری درباره خدمات ماشینکاری CNC سفارشی ما کسب کنید و ببینید چگونه میتوانیم پروژه شما را پشتیبانی کنیم.

مورد |

فورجینگ سفارشی قطعات مuting ماشینکاری cnc خدمات تولید |

نام برند |

ویویه |

شماره مدل |

OEM |

درمان سطحی |

پرتاب شن یا پوسته کاری |

نام محصول |

قطعات چرخاندن ماشینکاری CNC سفارشی |

خدمات |

کاربردی سفارشی CNC |

کلمه کلیدی |

قطعات فورجینگ گرم سفارشی |

ماشینکاری |

مرکز ماشینکاری CNC |

فرآیند |

آهنگری + ماشینکاری (در صورت نیاز) + تیمار سطح |

تجهیزات |

تراش CNC |

نوع |

قطعات OEM |

ماده اصلی |

آهن |

مورد |

اجزای مutes |

تمام محصولات ما تحت تولید نیمه خودکار با دقت، که پنج طبقه و مساحت 4810 متر مربع دارد، ساخته میشوند. ما دارای انواع تجهیزات خودکار دقیق هستیم: 120 مجموعه لث اسنک، مراکز ماشینکاری CNC، ماشینهای ضربهزنی و فرآوری فشاری، ماشینهای رولهبندی و دیگر ماشینآلات فرآیندی. این تجهیزات ظرفیت ماهانه 3,000,000 واحد را دارا هستند تا با سفارشات حجمی شما هماهنگ شوند. همچنین بسیاری از تجهیزات آزمایشی برای تضمین کیفیت وجود دارد. مانند: سه بعدی، پروژکتور نوری، سurfagauge، سclerometer، آزمایشگر تنش و غیره. کنترل کیفیت: تمام مهندسان و کارشناسان کیفیت ما در هر مرحله مهندسی و تولید به صورت استاندارد ISO مشارکت و فعال هستند. مواد موجود: مس، فولاد عادی، آلیاژ فولاد، فولاد ضد زنگ زنی و آهن، آلومینیوم، روی؛ پوششهای سطحی موجود: پُستهبرداری دقیق، الکترولیت-پُستهبرداری، کروم، پلاست کردن روی، پلاست کردن نیکل، اکسیداسیون آلومینیوم. فرآیندهای موجود: فرآیندهای فلزی شامل ماشینکاری، ضربهزنی، جوشکاری و فشارگرم، تزریق پلاستیک متخصصانه، و پلاست کردن سطحی. سفارشات OEM خوش آمدید. اگر پروژه جدیدی دارید، لطفاً فایل طرح 2D یا 3D (STP، IGS) خود را به ما ارسال کنید، ما در مدت زمان 24 ساعت به شما پیشنهاد قیمت خواهیم داد.

پاسخ A1: محصولات اصلی ما قطعات فشاربری برنج و قطعات ماشینکاری هستند.

سوال 2: چگونه کیفیت هر فرآیند را تضمین میکنید؟

پاسخ 2: هر فرآیند توسط بخش بازرسی کیفیت ما بررسی میشود که کیفیت هر محصول را تضمین میکند. در تولید محصولات، ما به صورت شخصی به کارخانه میرویم تا کیفیت محصولات را بررسی کنیم.

سوال 3: زمان تحویل شما چقدر است؟

پاسخ 3: زمان تحویل ما معمولاً 30 تا 45 روز است. یا بر اساس مقدار.

سوال 4: روش پرداخت شما چیست؟

پاسخ 4: 30٪ ارزش T/T مقدم و بقیه 70٪ بر اساس کپی B/L.

برای سفارشهای کوچک کمتر از 1000 دلار آمریکا، پیشنهاد میکنیم 100٪ مبلغ را مقدم پرداخت کنید تا از هزینههای بانکی کاسته شود.

سوال 5: آیا میتوانید نمونه ارائه دهید؟

A5: البته، نمونه ما پس از دریافت هزینه ابزارسازی و هزینه های کوریه ارائه می شود.