18 years OEM Mass production Aluminum Parts rapid Prototyping Manufacturing CNC machining service

- Overview

- Related Products

Weiyue is a trusted brand with 18 years of experience in providing high-quality OEM mass production of aluminum parts. We specialize in rapid prototyping and CNC machining services, helping businesses bring their ideas to life quickly and efficiently. Our expertise and advanced technology allow us to deliver precise aluminum components for a wide range of industries, including automotive, electronics, aerospace, and more

At Weiyue, we understand the importance of accuracy and reliability in manufacturing. With nearly two decades in the field, we have developed strong capabilities in CNC machining, which lets us create complex aluminum parts with tight tolerances and smooth finishes. Whether you need a single prototype or large-scale production, our state-of-the-art CNC machines can handle your order efficiently without compromising on quality

Our rapid prototyping services are designed to speed up your product development process. We work closely with you from the initial design to produce quick, accurate samples. This approach helps you test and improve your design before moving to full production, saving you time and money. We use cutting-edge software and machinery that allow quick turnaround times while maintaining high standards

Weiyue’s aluminum parts are known for their strength, durability, and lightweight features. Aluminum is a popular choice because it offers excellent corrosion resistance and thermal conductivity, making it suitable for demanding environments. We carefully select high-grade aluminum materials to ensure that every part meets industry standards and customer requirements. Our skilled engineers also provide valuable insights during the development phase, ensuring the final product is perfectly suited for your needs

Customer satisfaction is at the heart of what we do. Weiyue offers flexible manufacturing solutions tailored to different project sizes and complexities. From custom designs to precise mass production runs, we maintain a consistent quality control process. Every part goes through detailed inspection to ensure it meets the exact specifications before shipment

Weiyue combines 18 years of experience, advanced CNC machining technology, and rapid prototyping expertise to deliver superior aluminum parts. Whether you are developing a new product or need reliable mass production, Weiyue is your go-to partner for efficient, high-quality aluminum manufacturing services. Contact us today to learn how we can support your project from start to finish

OEM/ODM Service |

· According to customers' drawings · According to customers' samples |

| Production range | Auto parts, industrial metal parts, machine fitting and hardware parts |

| Available materials | Steel alloy, brass, aluminum/zinc alloy, iron and stainless steel |

| Manufacturing process |

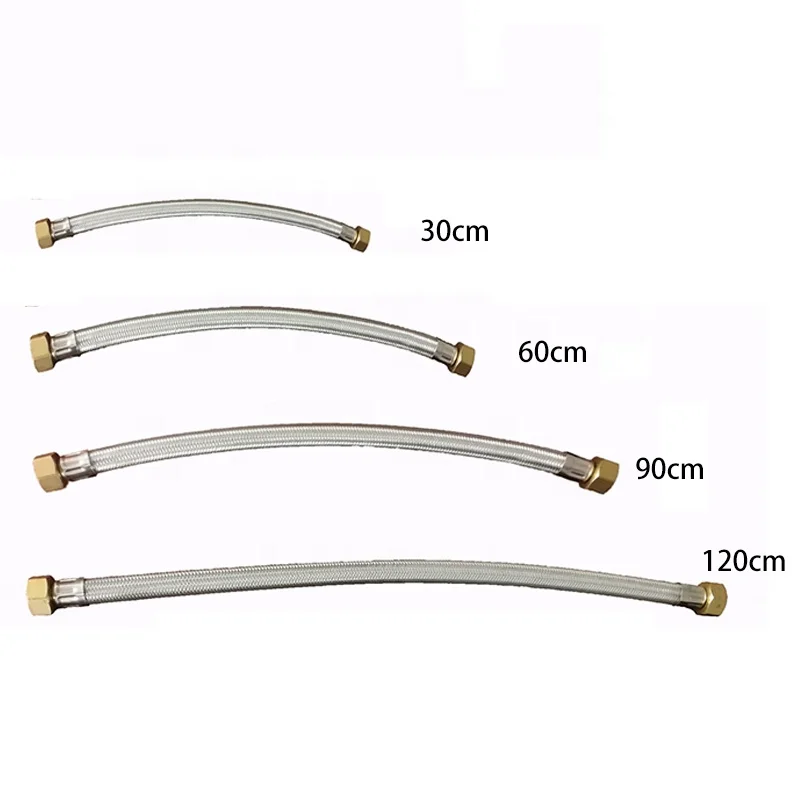

· Hot forging + machining · Warm/cold compressing + machining · Sheet stamping + machining · Bar stock + cnc machining · Braiding stainless steel wire |

| Available production processes |

Annealing, heat treatment, sand-blasting, surface plating, polish, QC testing and packing Available finishes fine polished, chrome, zinc, nickel plating, anodize with all kinds of customized colors, etc |

| Target customer | Direct manufacturers, EAU purchase amount from $0.2 million to 2 million |

| Delivery time | 2-6 weeks for samples, 4-8 weeks for mass-production delivery |

| Quanlity System | ISO 9001: 2019 |

| Mainc processs | Forging, stamping, cold or warm pressing, machining |

| Equipment | Forging machine, CNC milling machine, meter lathes, automatic lathing machines, sand blasting machine, polishing machine |

| Surface Treatment | Polishing, Painting, Chroming, Anodizing, Brushing, Silk Screening, Water Transfering, Laser Cutting, Leather Covering, Texture, Sanblasting, Gilding, UV Painting |

| QC control | 100% inspection on critical dimensions with Supply chain process PPAP |

| We Promise | All customer-centric, never for short-term profit, and sell long-term benefits |

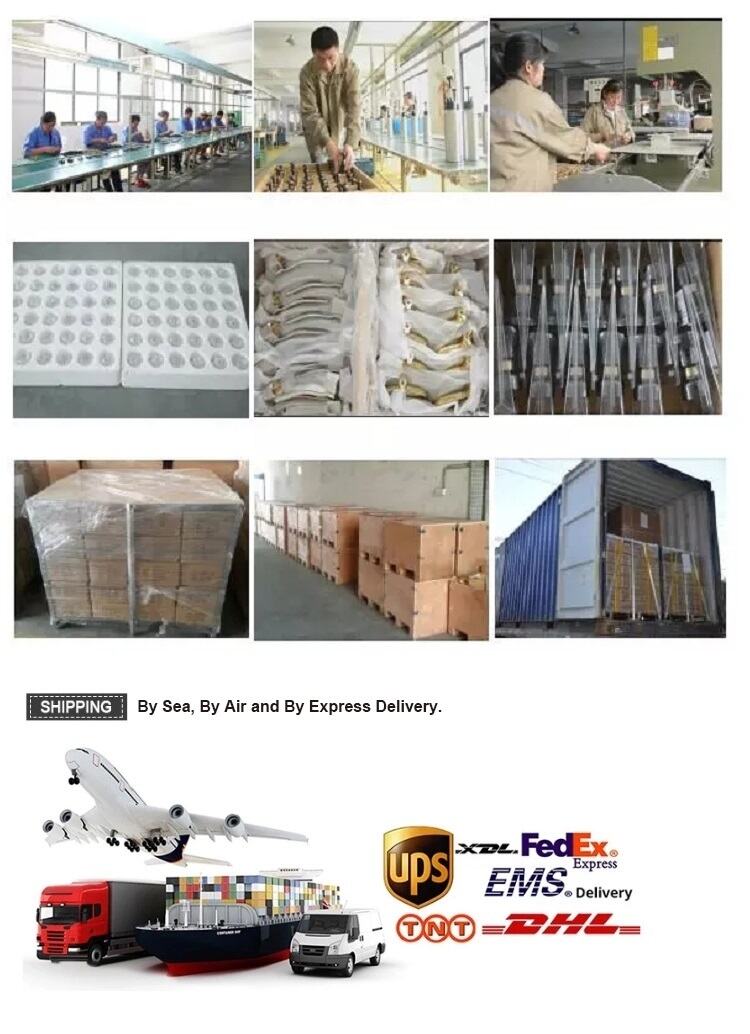

Since 2001, Cixi Weiyue Matel Product Co., Ltd. has offered quality precision machining service, Equipped with over 120 sets of CNC machine and punching machines, 100 sets of instrument lathe, 2 sets of assembly line, manufactured under ISO9001:2015 certified factory they have a monthly capacity of 10,000,000 units, to machine your volume orders. The current main products including fittings, nozzles, sparyers

Since 2001, Cixi Weiyue Matel Product Co., Ltd. has offered quality precision machining service, Equipped with over 120 sets of CNC machine and punching machines, 100 sets of instrument lathe, 2 sets of assembly line, manufactured under ISO9001:2015 certified factory they have a monthly capacity of 10,000,000 units, to machine your volume orders. The current main products including fittings, nozzles, sparyers

Our dedication, plus the company's knowledge and experience, have resulted in satisfied customers. We are proud that we have been producing custom-made fittings for our USA client over six years and the annual order quantities are over Ten million pieces. Now, we are qualified supplier of FITT

PRODUCTION EQUIPMENT |

TYPE |

QTY |

AVAILABLE SIZE |

TOLERANCE CONTROL |

AVAILABLE MATERIAL |

CNC lathe |

Turning |

120 SETS |

MAX OD 120mm |

Min +/-0.01mm |

Brass, carbon steel, S. S, zinc, AL |

Punch |

Hot forging |

32 SETS |

60-80 tons |

Normal +/-0.05mm |

Brass, steel, S. S |

Cold forging |

15 to 100 tons |

Normal +/-0.05mm |

Brass, steel, S. S |

||

Hydraulic press machine |

Hot & cold pressing |

2 SETS |

315 tons & 500 tons |

Min +/-0.02mm |

Brass, steel, S. S, AL |

Rolling machine |

Threading and diamond rolling |

2 SETS |

MAX OD 25MM |

Normal +/-0.05mm |

Brass, steel, S. S, Zinc |

Annealing machine |

Band turning |

2 LINES |

6m long |

100-800°C |

Brass, steel, AL |

Q: Are you a factory or trading company

A:We are a factory in Zhejiang of China, welcome to visit us

Q: How can I get the quotation

A:We will submit the quotation in 24 hours if getting detailed information during working days In order to quote for you earlier, please provide us the following information together with your inquiry

1) 3D Step of Files and 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity per order/per month/annual

5) Any special demands or requirements, such as packing, labels, delivery, etc

Q: What are the main oversea markets of WY

A: Currently WY regular oversea customers are from the US, the UK, Italy, Germany, France and India etc

Q: How you do the quality control

A:1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per the parameters list and critical dimensions requested by customers, to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out

Q: What should we do if we receive defective products

A: If receive defective product, please send us the photos, we will feedback to our engineers and QC departments and solve the problems ASAP

Q: How to pack the products

A: For products, we will pack into standard export cartons or as per customer’s request to pack