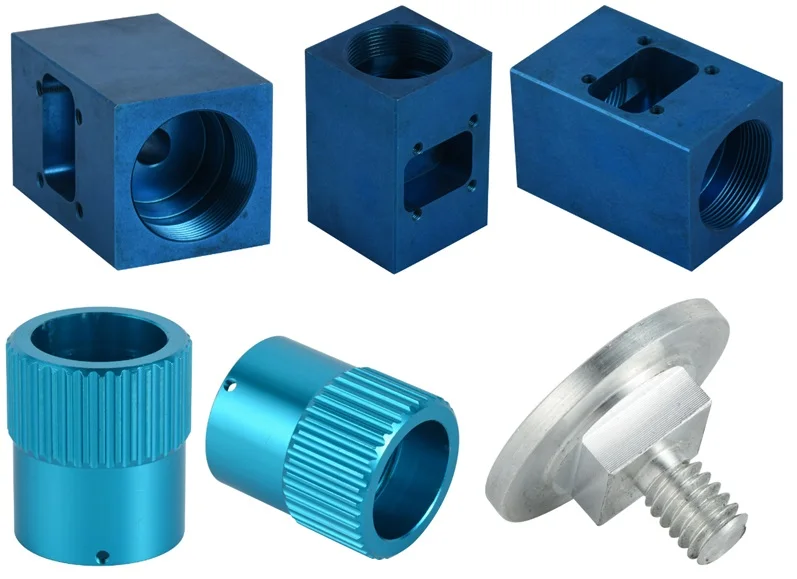

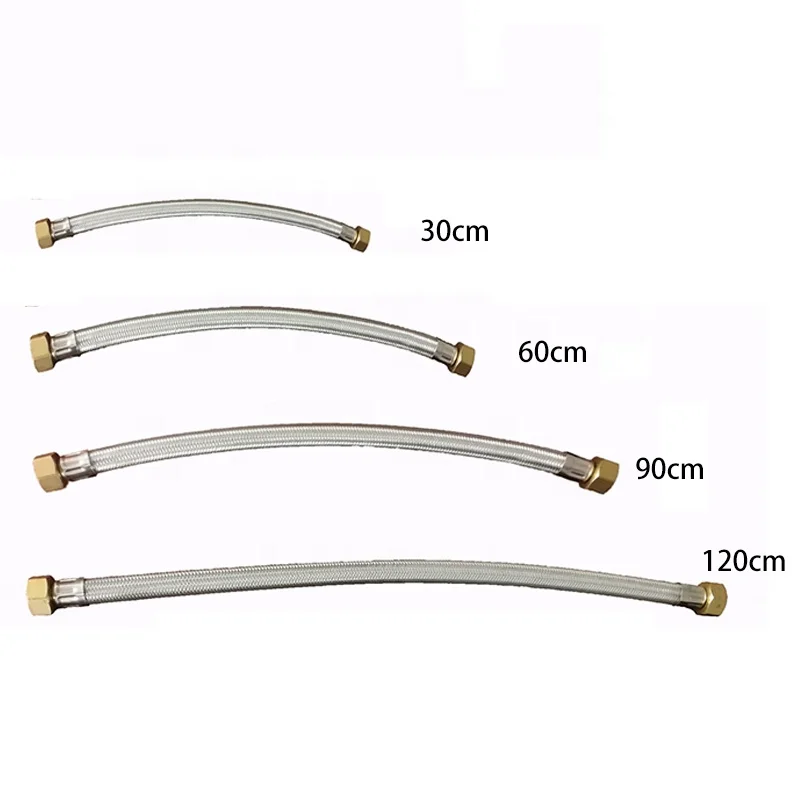

Custom Made Factory High Precision Aluminum Forging Parts Hot Forging and Cnc Machining Parts Service

- Overview

- Related Products

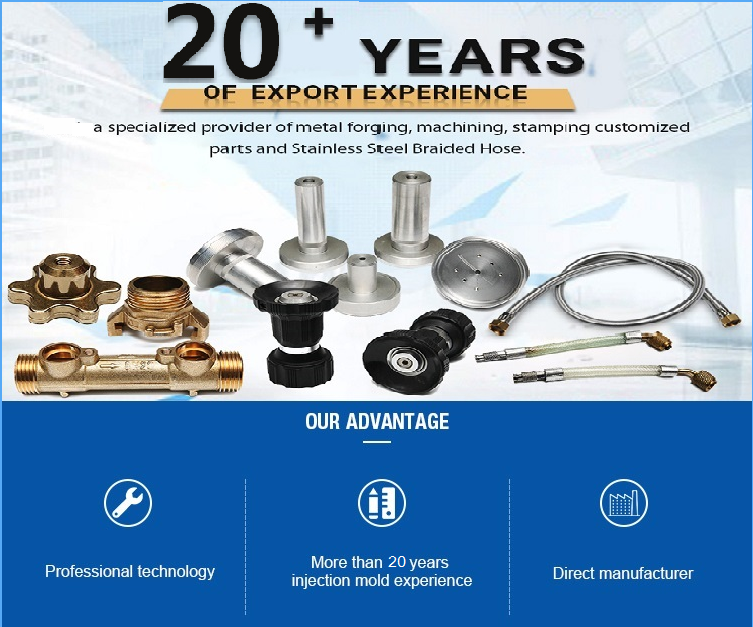

Weiyue Custom Made Factory offers high precision aluminum forging parts that meet the needs of various industries. Our products are made using advanced hot forging and CNC machining processes, ensuring top quality and reliable performance. Whether you need small or large aluminum parts, we provide custom solutions tailored to your exact specifications

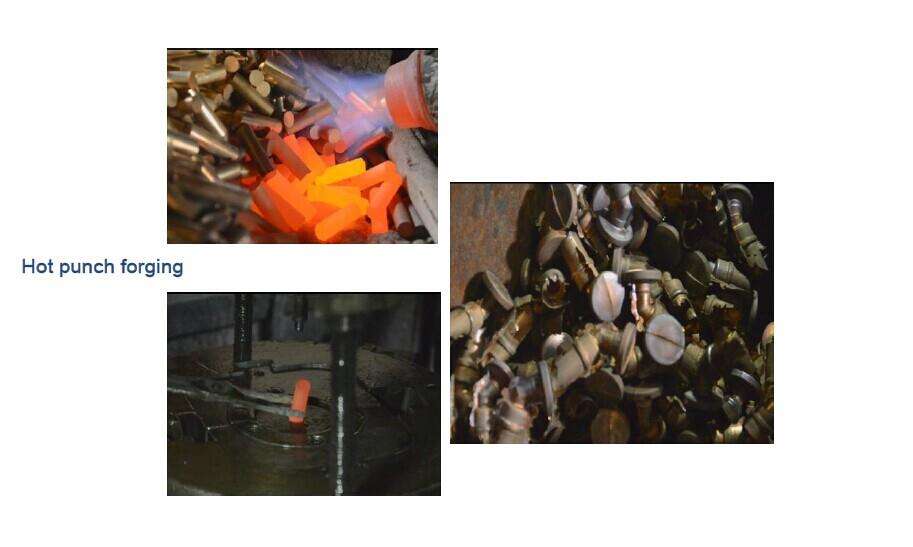

At Weiyue, we specialize in manufacturing aluminum forging parts with great attention to detail. Hot forging is a key method we use to shape metal at high temperatures, which makes the parts stronger and more durable. This process improves the material’s internal structure, resulting in parts that can withstand tough conditions and heavy use. After forging, our skilled technicians use CNC machining to achieve precise dimensions and smooth finishes. CNC machining allows us to create complex shapes and tight tolerances that meet your exact requirements

We serve a wide range of industries, including automotive, aerospace, machinery, electronics, and more. Our aluminum forging parts can be used in engine components, structural parts, housings, connectors, and other critical applications. Because we control the entire manufacturing process from start to finish, we guarantee consistent quality, fast turnaround times, and competitive pricing

Customer satisfaction is very important to us at Weiyue. We work closely with you to understand your needs and provide expert advice on design, materials, and manufacturing techniques. Our team uses the latest technology and equipment to produce parts that meet international quality standards. We also offer prototyping and small-run production runs, so you can test the parts before placing larger orders

Choosing Weiyue for your custom aluminum forging parts means you get a reliable partner committed to delivering high precision and durable solutions. Our aluminum parts are lightweight, strong, and corrosion-resistant, making them ideal for many applications. With our hot forging and CNC machining capabilities, you can trust that every part will be made accurately and efficiently

Weiyue Custom Made Factory provides high-quality aluminum forging parts through hot forging and CNC machining services. We offer custom solutions, quick delivery, and excellent support to help your project succeed. Contact us today to learn more about how our aluminum parts can meet your exact needs and improve your products

Place of Origin |

Zhejiang China |

Keywords |

Aluminum forging parts |

Software/format |

PRO/E, Auto CAD, Solid works, IGS, UG, CAD/CAM/CAE |

Tolerance |

0.01~0.05mm, can customize as per request |

Dimension |

Customized, MAX OD 300*300MM |

Test equipment |

Measurement instrument, projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin guage etc |

Prouduciton Equipments |

CNC Machining lathe, Hot forging & Hydraulic compress machine, Auto-milling machine, Drilling and Milling Center, Braid machine |

Material |

Aluminum, Brass, Bronze, Copper, Stainless Steel, Steel Alloy, etc |

Surface Treatment |

Zinc/Nickel/Chrome Plating, Passivation, Hardening, Clear Anodizing, Black Anodizing, Black Oxide, Coating, Degreasing, Brushing, Electronic |

Certificate |

ISO9001:2015 |

Packing |

Inner packing: Plastic/paper wrap, bubble bag, PE foam, EPE cotton, PPbag Custom made Outer packing: carton box, steel pallet etc |

All our products are manufactured under Precision manufacturing, which have five floors of 4810 square meters. Owning various types of precision automatic equipments: 120 sets of CNC Lathe, CNC machining centers, forging and Stamping Machines, thread rolling machines and other processing machines. those have a monthly capacity of 3,000,000 units, to match your volume orders, There are also lots of testing equipment for quality assurance. Such as: three dimensional, optical Projector, Surfagauge, sclero-meter, Tension tester, etc. Quality Control All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard. Available materials: brass, mild steel, steel alloy, stainless steel and iron, aluminum, zinc; Available surface finish: fine polish, electrolyte-polish, chrome, zinc plating, nickel plating, aluminum oxidation. Available processes: metal processing includes machining, stamping, die-cast and hot-press, expert plastic injection, and surface plating. OEM orders are welcome Contact us NOW If you have new project please send your 2D or 3D drawing STP, IGS file to us, we will be quote to you in 24hours

A1:Our main products are brass forging parts and machined parts

Q2. How to ensure that every process's quality

A2:Every process will be checked by our quality inspection department which insures every product's quality. In the production of products, we will personally go to the factory to check the quality of products

Q3. How long is your delivery time

A3:Our delivery time is generally 30 to 45 days. Or according to the quantity

Q4. What is your payment method

A4:30% value of T/T in advance and other 70% balance on B/L copy

For small order less than 1000USD, would suggest you pay 100% in advance to reduce the bank charges

Q5. Can you provide a sample

A5:Sure, Our sample is provided after receiving the tooling cost and courier fees