- Overview

- Related Products

Introducing Weiyue’s Factory Directly Provided Customized Steel Metal Hot Forging Parts – your reliable solution for high-quality metal components crafted to meet your exact needs

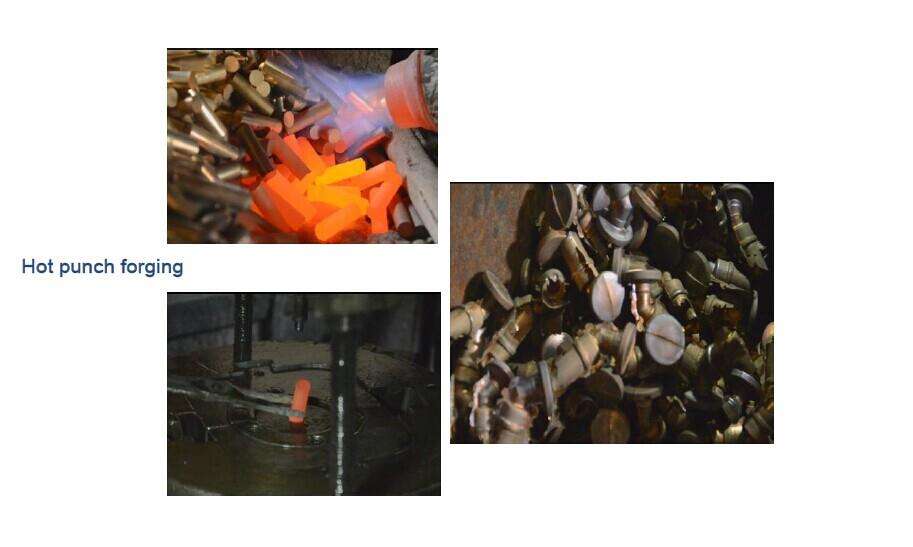

At Weiyue, we specialize in manufacturing steel metal parts using hot forging technology. Hot forging is a process where metal is heated to a high temperature and then shaped under pressure. This method improves the strength and durability of the metal, making the parts stronger and longer-lasting compared to those made by other methods. Whether you need small or large pieces, simple or complex shapes, Weiyue can customize parts that fit your unique requirements

By choosing Weiyue’s factory directly provided parts, you benefit from competitive prices because you are cutting out the middleman. You get direct access to our skilled engineers and advanced machines, ensuring superior quality every time. Our experienced team works closely with you throughout the entire process, from design and material selection to final production, to ensure the parts meet your exact specifications

Our steel hot forging parts are ideal for various industries, including construction, automotive, machinery, agriculture, and more. These parts can be used for gears, shafts, bolts, connectors, and many other important components where strength and precision are key. Weiyue uses high-grade steel materials that comply with industry standards, ensuring our parts withstand heavy use and harsh environments

Customization is what sets Weiyue apart. We understand every project has different needs, so we offer tailor-made solutions. You can choose the size, shape, weight, and finish of the parts. We also provide surface treatments like painting or coating to protect against rust and wear. Our quality control team carefully inspects each batch to guarantee consistency and reliability, giving you peace of mind

Ordering from Weiyue is simple and efficient. With factory direct supply, you enjoy shorter lead times and faster delivery. Our friendly customer service team is ready to assist you with any questions or special requests, making sure your order process is smooth from start to finish

Choose Weiyue for your customized steel metal hot forging parts and experience the benefits of strong, durable, and precisely made components at factory direct prices. Contact us today to discuss your project and get a free quote

Place of Origin |

Zhejiang China |

Keywords |

Customized steel metal hot forging parts |

Software/format |

PRO/E, Auto CAD, Solid works, IGS, UG, CAD/CAM/CAE |

Tolerance |

Forging normal at +/-0.30mm & Min 0.05mm Machining at 0.01~0.05mm, can customize as per request

|

Dimension |

Customized, MAX weight 3kgs for forging, machining Max OD 300*300MM |

Test equipment |

Measurement instrument, projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin guage etc |

Prouduciton Equipments |

CNC Machining lathe, Hot forging & Hydraulic compress machine, Auto-milling machine, Drilling and Milling Center, Braid machine |

Material |

Aluminum, Brass, Bronze, Copper, Stainless Steel, Steel Alloy, etc |

Surface Treatment |

Zinc/Nickel/Chrome Plating, Passivation, Hardening, Clear Anodizing, Black Anodizing, Black Oxide, Coating, Degreasing, Brushing, Electronic |

Certificate |

ISO9001:2015 |

Packing |

Inner packing: Plastic/paper wrap, bubble bag, PE foam, EPE cotton, PPbag Custom made Outer packing: carton box, steel pallet etc |

All our products are manufactured under Precision manufacturing, which have five floors of 4810 square meters. Owning various types of precision automatic equipments: 120 sets of CNC Lathe, CNC machining centers, forging and Stamping Machines, thread rolling machines and other processing machines. those have a monthly capacity of 3,000,000 units, to match your volume orders, There are also lots of testing equipment for quality assurance. Such as: three dimensional, optical Projector, Surfagauge, sclero-meter, Tension tester, etc. Quality Control All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard. Available materials: brass, mild steel, steel alloy, stainless steel and iron, aluminum, zinc; Available surface finish: fine polish, electrolyte-polish, chrome, zinc plating, nickel plating, aluminum oxidation. Available processes: metal processing includes machining, stamping, die-cast and hot-press, expert plastic injection, and surface plating. OEM orders are welcome Contact us NOW If you have new project please send your 2D or 3D drawing STP, IGS file to us, we will be quote to you in 24hours

A1:Our main products are brass forging parts and machined parts

Q2. How to ensure that every process's quality

A2:Every process will be checked by our quality inspection department which insures every product's quality. In the production of products, we will personally go to the factory to check the quality of products

Q3. How long is your delivery time

A3:Our delivery time is generally 30 to 45 days. Or according to the quantity

Q4. What is your payment method

A4:30% value of T/T in advance and other 70% balance on B/L copy

For small order less than 1000USD, would suggest you pay 100% in advance to reduce the bank charges

Q5. Can you provide a sample

A5:Sure, Our sample is provided after receiving the tooling cost and courier fees