- Overview

- Related Products

Weiyue is a trusted manufacturer specializing in steel forging and precision machining services. With years of experience in the industry, Weiyue has built a strong reputation for delivering high-quality steel parts that meet the exact needs of various customers. Whether you are looking for strong, durable forged steel components or precision-machined parts, Weiyue offers reliable solutions designed to perform well in demanding applications.

Our steel forging services involve shaping steel under high pressure to create parts that are tough and long-lasting. Forged steel parts made by Weiyue are known for their strength and resistance to wear, making them ideal for use in heavy machinery, automotive, construction, and many other industries. We use advanced forging equipment and strict quality controls to ensure each piece meets the highest standards. This means that customers can count on our forged parts to provide excellent performance and longevity.

In addition to forging, Weiyue also provides precision machining services. Precision machining is a process that creates parts with exact dimensions and smooth finishes, which is important for parts that need to fit perfectly and work smoothly with other components. Our skilled technicians use modern computer-controlled machines to shape steel and other metals into precise forms. This allows us to produce complex parts quickly and with great accuracy, meeting the specific needs of each client.

At Weiyue, we are committed to quality and customer satisfaction. Our professional team works closely with customers to understand their requirements and deliver products that meet or exceed expectations. We use high-quality raw materials and follow strict manufacturing processes to ensure every product is reliable and durable. Whether you are ordering a small batch or large production runs, Weiyue maintains consistent quality throughout.

Weiyue’s products include a wide range of steel forged components such as shafts, gears, connecting rods, flanges, and other custom parts. Our machining services cover turning, milling, drilling, grinding, and finishing work to produce components used in engines, machinery, tools, and more. No matter the complexity, Weiyue has the tools, skills, and knowledge to get the job done right.

Choosing Weiyue means choosing a partner who understands the importance of sturdy, precise steel parts. Our steel forging and precision machining services help businesses improve their products’ strength, durability, and performance. Contact Weiyue today to learn more about our products and how we can support your manufacturing needs with expert steel forging and machining solutions

Steel forging and machining products manufacturer

Steel forging and machining products manufacturer

Cixi Weiyue Metal Product Co., Ltd. formerly known as Cixi Fule Flooding Equipment Co., Ltd

set up in the year of 2001, is one of the manufacturing factory main provide customization metal die-casting, forging, cold or warm form pressing, stamping and precision CNC lathe machining service, We have a complete in-house manufacturing system-from products design, making, testing to parts mass-production

Our factory have been approved by ISO9001:2008 supervisory system, all our workshop and products are manufactured under it. Main processes workshop include precision forging and stamping workshop, cold/ward forming press workshop, CNC lathe machining workshop, and inspection and packing workshop

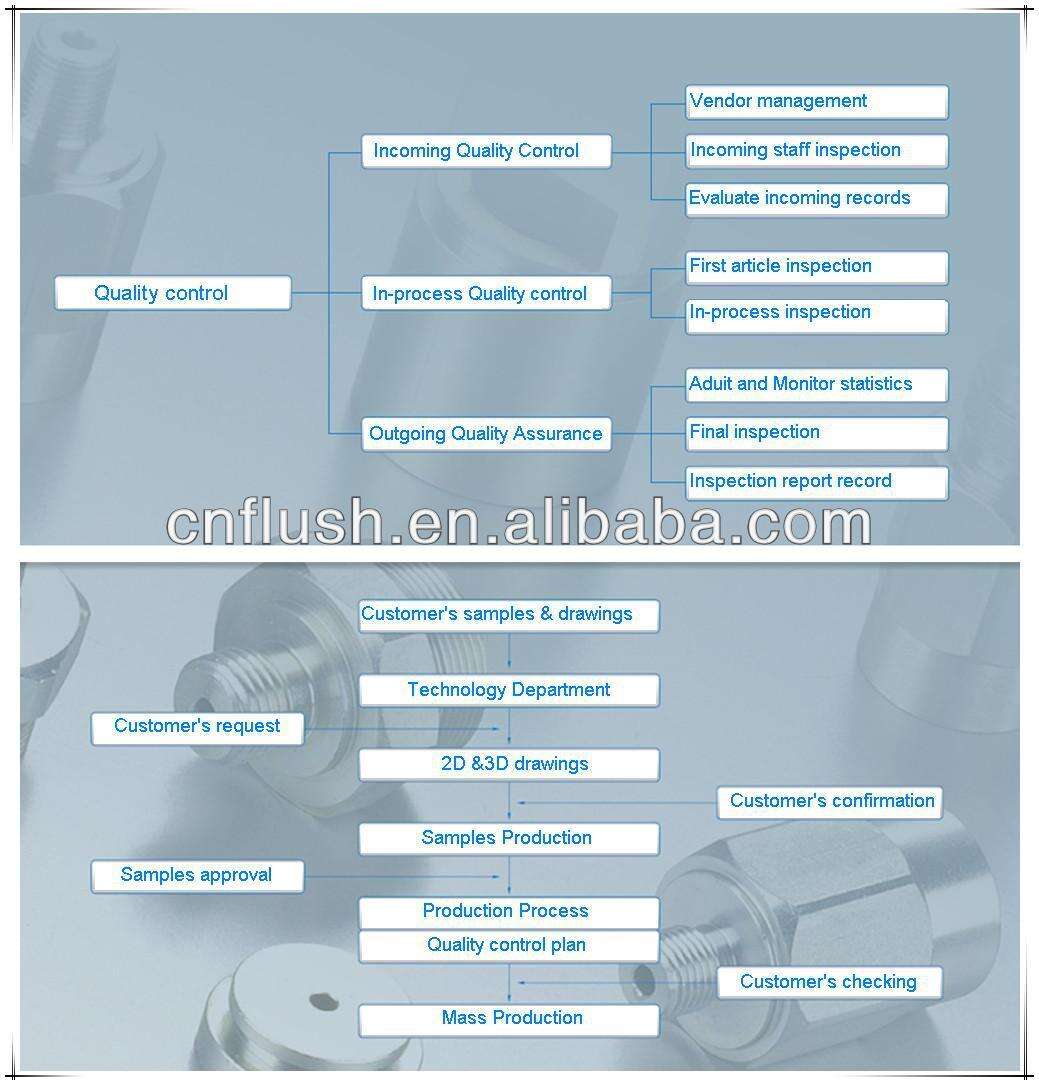

Quality Control

All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard, to make sure that only quality parts leave our plant

Production Equipment and ability

PRODUCTION EQUIPMENT |

TYPE |

QTY |

SIZE |

TOLERANCE |

CNC Lathe |

turning |

120 sets |

MAX OD 120mm |

Min +/-0.01mm |

Punch |

hot forging |

3 sets |

60-80 tons |

+/-0.05mm |

cold stamping |

29 sets |

15-100 tons |

+/-0.05mm |

|

Hydraulice press machine |

Hot&cold press |

2 sets |

315-500 tons |

+/-0.02mm |

Rolling machine |

Threading and diamond rolling |

2sets |

Max OD 25mm |

+/-0.05mm |

Factory Production work shop and capacity

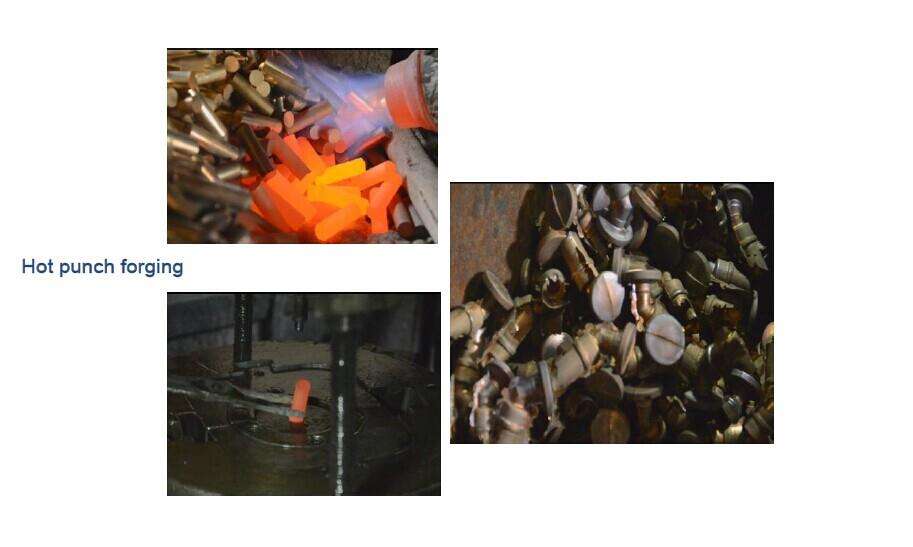

Precision forging, that include puch hot forging and press forging, have 3 sets of 63 tons to 125 tons forging machine, and 2 sets of 300 tons and 500 tons of hydraulic machine for cold or warm form press forging process. Available to produce the parts from 20g to 2500g

Precision CNC lathe machining workshop, have 120 sets of CNC lathe, available to contrail the MIN tolerance at +/-0.01mm.

Metal stamping workshop

have 17 sets of stamping machine from 6.3 tons to 125 tons, those contain 2 sets of 60 tons precision punching machine for stamping

Inspection, assembly and packing workshop.

Other custom forging and precision machining products show

Contact us NOW

We are always try our best to provide you premium quality products with competitive price. Should any requirement, please do not hesitate to contact us

Business Types

OEM Manufacturer

Exporter

Markets

World Wide

FAQ:

Q1. What is your main products

A1:Our main products are hot or cold forging parts, stamping parts and cnc machining parts

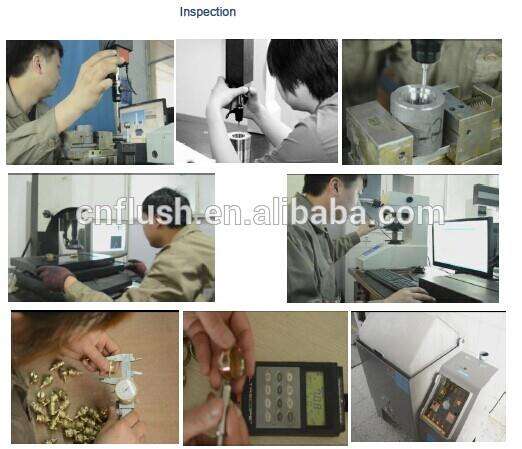

Q2. How to ensure that every process's quality

A2:Every process will be checked by our quality inspection department which insures every product's quality

Q3. How long is your delivery time

A3:Our delivery time is generally 35 to 45 days. Or according to the quantity

Q4. What is your payment method

A4:30% value of T/T in advance and other 70% balance on B/L copy

For small order less than 1000USD, would suggest you pay 100% in advance to reduce the bank charges

Q5. Can you provide a sample

A5:Sure, Our sample is provided after receiving the tooling cost and courier fees