OEM Factory Customized Auto Parts & Machinery Parts Steel Hot Forging on Aluminum Alloy Metal Copper Iron

- Overview

- Related Products

Weiyue is a trusted brand known for its high-quality OEM factory customized auto parts and machinery parts made through steel hot forging. Our products are designed to meet the needs of various industries, including automotive, machinery, and manufacturing. Using advanced hot forging techniques, we create strong and durable parts from different metals such as aluminum alloy, copper, and iron. This ensures that every piece we produce offers excellent performance and long-lasting reliability.

Our process begins with selecting the best raw materials. We carefully choose steel, aluminum alloy, copper, and iron that meet strict quality standards. These metals go through a hot forging process, where they are heated to high temperatures and shaped under heavy pressure. This method improves the metal’s strength and toughness, making the parts more resistant to wear, impact, and harsh working conditions.

Weiyue’s OEM service means we work closely with clients to create custom parts that fit their specific needs. Whether you need auto parts for cars, trucks, or industrial machinery components, we tailor each product to exact designs and dimensions. Our experienced team can handle different sizes and shapes, ensuring compatibility and optimal performance for your machines. We pay attention to every detail, from the initial design to final inspection, to ensure the parts meet all industry standards.

One key benefit of our steel hot forged parts is their high durability. Compared to parts made by casting or machining, hot forged parts have a finer grain structure, which reduces the risk of cracks and breaks. This makes them ideal for critical automotive parts like gears, shafts, and connecting rods, as well as machinery parts that require strength and resistance to heavy loads.

Weiyue’s commitment to quality extends to all metals we use. Our aluminum alloy parts are lightweight yet strong, perfect for reducing vehicle weight and improving fuel efficiency. Copper parts offer excellent electrical conductivity and corrosion resistance, useful in electrical machinery and components. Iron parts provide solid strength and are commonly used in heavy machinery and construction equipment.

Weiyue delivers customized OEM auto and machinery parts through advanced steel hot forging of aluminum alloy, copper, and iron. Our products are built to last, designed with precision, and manufactured to meet your unique requirements. Choose Weiyue for reliable, high-performance parts that help your machines run smoothly and efficiently

| Material | steel #20, #45, Q235 |

| Type | steel hot forging |

| Process | hot forging & cnc machining |

| Size | customized |

| Finish | sand-blasting, plating, polished, or as request |

| Tolerance | +/-0.01mm -- +/- 0.005mm - depends on your product |

| Certificate | ISO 9001 : 2015 |

| QC control | 100% inspection on critical dimensions |

| Cost control | Most efficient production process design |

| Management | Skilled workers and Rich experienced staff |

| Supply chain process | PPAP |

| Advantage | 100 sets CNC machines for high output with quick delivery |

| Experience | Providing CNC Engineering Metal Parts for over 17 years |

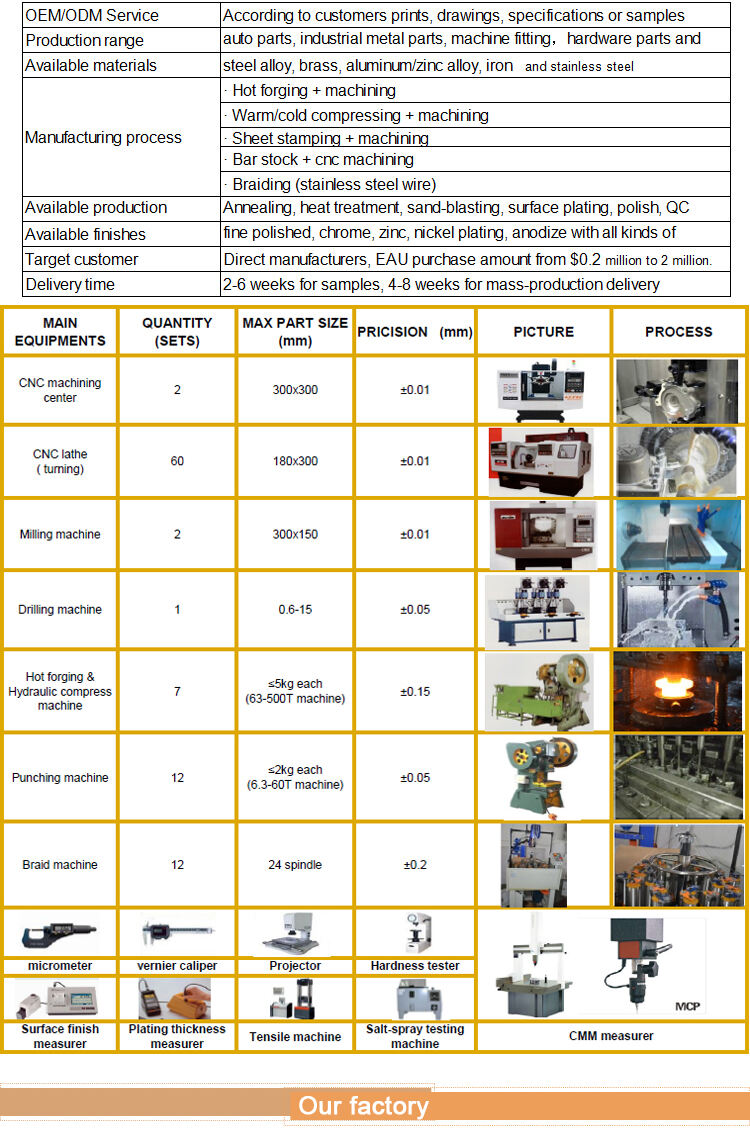

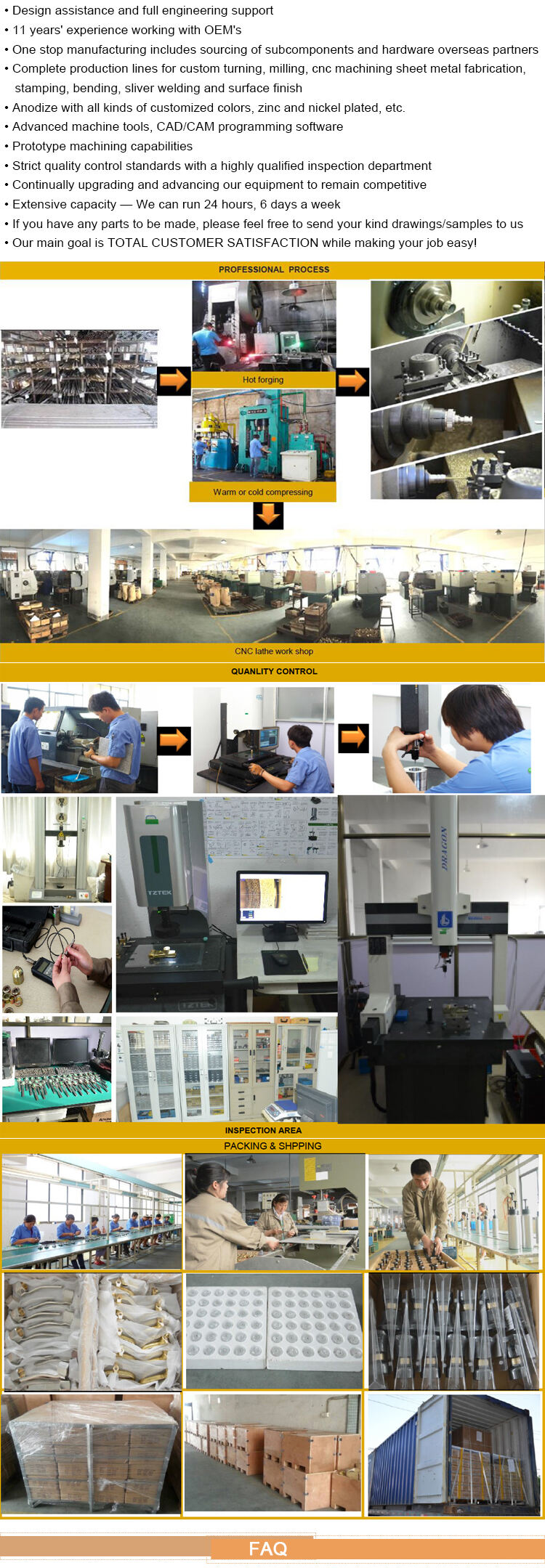

Founded in 2001, Cixi Weiyue Metal Product Co., Ltd. is a specialized provider of metal forging, machining, stamping customized parts and Stainless Steel Braided Hose. We have a complete in-house manufacturing system - from products design, making, testing, to parts processing and assembly

All our products are manufactured under ISO9001:2015 certified, which have five floors of 4810 square meters. Owning various types of precision automatic equipments: 120 sets of CNC Lathe, CNC machining centers, forging and Stamping Machines, thread rolling machines and other processing machines. There are also lots of testing equipment for quality assurance. Such as: three dimensional, optical Projector, Surfagauge, sclero-meter, Tension tester, etc

Quality Control All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard. OEM orders are welcome Contact us NOW If you have new project please send your 2D or 3D drawing (STP, IGS) file to us, we will be quote to you in 24hours

1. Where is your location

We are located in Ningbo City of China and are closed to Ningbo port It takes 2 hours by car.

2. Are you trading company or manufacturer

We are a manufacturer.

3. Will my drawing be safe after you get it

Yes. We will not release your design to the third party unless with your permission.

4. How long does it take to receive samples

A) Made from bar stock within 2 weeks

B) Made by dies usually 4-8 weeks

5. How to deal with the parts received when they are found to be in poor quality

Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non-conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time. The resulting transportation costs are borne by our company.

6. Why you limited the customer EAU purchase amount

We are the factory 100% produce the parts by ourselves to control the best quality, it cause the capacity limited.