- Overview

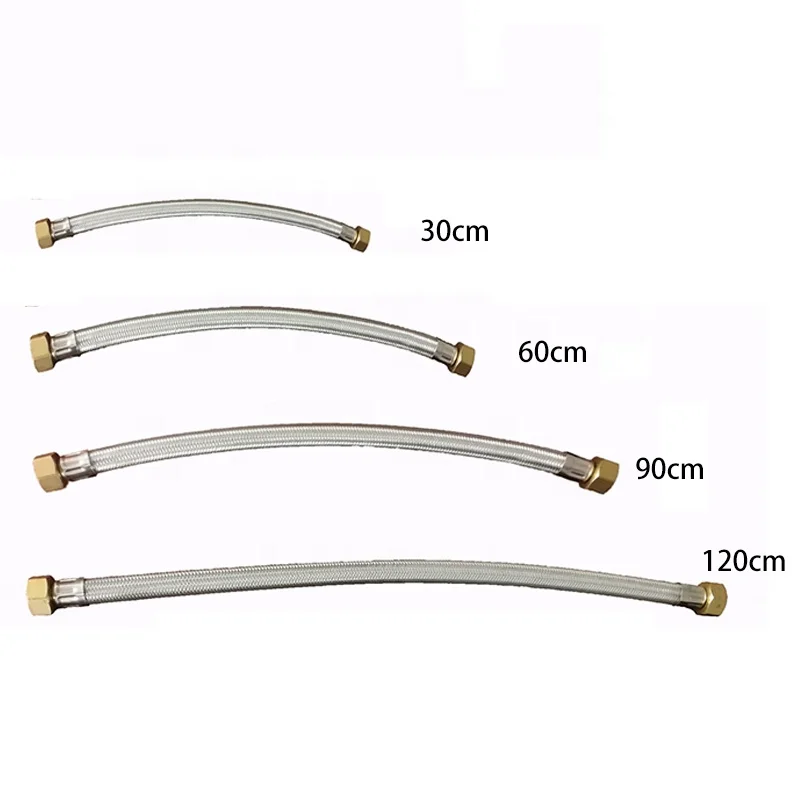

- Related Products

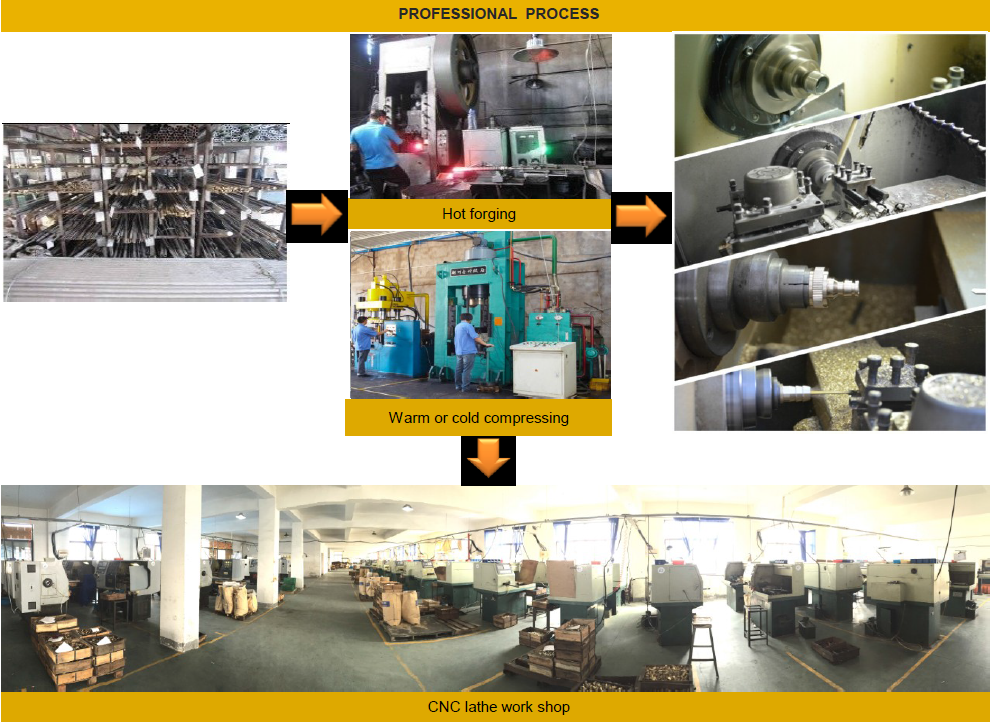

Hot forging + machining

Warm/cold compressing + machining

Sheet stamping + machining

Bar stock + cnc machining

Braiding stainless steel wire

Weiyue OEM Precision Aluminum CNC Milling Machining Parts

At Weiyue, we specialize in producing high-quality OEM precision aluminum CNC milling machining parts designed to meet the demands of various industries. Our parts are made with great attention to detail using advanced CNC milling technology, ensuring accuracy, consistency, and durability each time

Our precision aluminum parts are crafted from premium-grade aluminum materials, known for their lightweight nature and excellent strength. Aluminum is ideal for manufacturing because it offers good corrosion resistance, thermal conductivity, and electrical properties, making it suitable for a wide range of applications such as automotive, aerospace, electronics, medical devices, and industrial equipment

Using CNC (Computer Numerical Control) milling machines, our expert technicians can create complex shapes and fine features with tight tolerances. This process involves removing material from aluminum blocks with rotating cutting tools controlled by a computer program. CNC milling ensures that each part is produced exactly as per the design specifications, minimizing errors and waste

Weiyue’s CNC milling machining parts come in various sizes and shapes depending on customer needs. Whether you require small components for electronic devices or larger mechanical parts for industrial machines, we can customize the production process to suit your requirements. Our flexible OEM services mean we can handle both small and large production runs efficiently

Quality is our top priority. Every part undergoes strict inspection procedures to check its dimensions, surface finish, and mechanical properties before shipping. We use advanced measuring instruments and quality assurance protocols to guarantee that the parts meet industry standards and perform reliably in their intended use

Customers choose Weiyue for our commitment to excellence, fast turnaround times, and competitive pricing. Our experienced engineering team works closely with clients from the initial design phase to final production, ensuring that all technical requirements are understood and met. This collaborative approach helps deliver machining parts that truly fit their purpose

Weiyue OEM precision aluminum CNC milling machining parts offer a perfect combination of strength, precision, and versatility. With our cutting-edge CNC technology and professional craftsmanship, we provide parts that help your products work better and last longer. Contact Weiyue today to discuss your custom machining needs and experience top-quality aluminum components tailored just for you

We are the factory provide OEM precision aluminum cnc milling machining parts

Material: aluminium 6061, 6063, 7075

Min OD at 20mm

Max OD at 500mm

Weight from 20g to 2500g

Cold forming or warm forming with CNC machining

Hydraulic machine at 315 tons and 500 tons

Press tolerance min +/-0.02mm

Precision CNC machining: tolerance min +/-0.01mm

Should any parts need to press forming process, please feel free to contact us at any times

Cixi Weiyue Metal Product Co., Ltd, is a manufacturer main provide brass, steel, aluminum and S. S metal parts custom-made service, factory located in Cixi Ningbo with 4300M2 production facility, include hot forging, cnc machining processes and stamping from prototype to volume production. We don't offer any ready made parts and are manufacturing the custom parts from your drawings or existing samples. Cixi Weiyue Metal Product Co., Ltd, understand customer's competition of their industries and we always perceive how to intensify customer's business, ability, therefore our management aiming at "integrity, practicality and innovation" in order to achieve our quality policy of fully satisfying the customer needs. We've been able to provide total solutions to clients in a variety of industries. We're the right OEM for you, contact us today

| OEM/ODM Service | According to customers prints, drawings, specifications or samples |

| Production range | Auto parts, industrial metal parts, machine fitting and hardware parts |

| Available materials | Steel alloy, brass, aluminum/zinc alloy, iron and stainless steel |

| Manufacturing process | |

| Available production processes | Annealing, heat treatment, sand-blasting, surface plating, polish, QC testing and packing |

| Available finishes | Fine polished, chrome, zinc, nickel plating, anodize with all kinds of customized colors, etc |

| Target customer | Direct manufacturers, EAU purchase amount from $0.2 million to 2 million |

| Delivery time | 2-6 weeks for samples, 4-8 weeks for mass-production delivery |

| OUR TEAM | ||

| Department | Number of employees | Years of work in this field |

| General Manager | 1 | 16 |

| Vice-general Manager | 1 | 12 |

| Finance Dept. | 3 | 5-10 |

| Purchase Dept. | 2 | 5-10 |

| Technology Dept. | 3 | 8-16 |

| Sales Dept. | 3 | 8-12 |

| QC Dept. | 6 | 3-12 |

| Production Dept | 52-62 | 1-12 |

1. Where is your location

We are located in Ningbo City of China and are closed to Ningbo port It takes 2 hours by car

2. Are you trading company or manufacturer

We are a manufacturer

3. Will my drawing be safe after you get it

Yes. We will not release your design to the third party unless with your permission

4. How long does it take to receive samples

A. Made from bar stock within 2 weeks

B. Made by dies usually 4-8 weeks

5. How to deal with the parts received when they are found to be in poor quality

Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non-conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time. The resulting transportation costs are borne by our company

6. Why you limited the customer EAU purchase amount

We are the factory 100% produce the parts by ourselves to control the best quality, it cause the capacity limited