- Overview

- Related Products

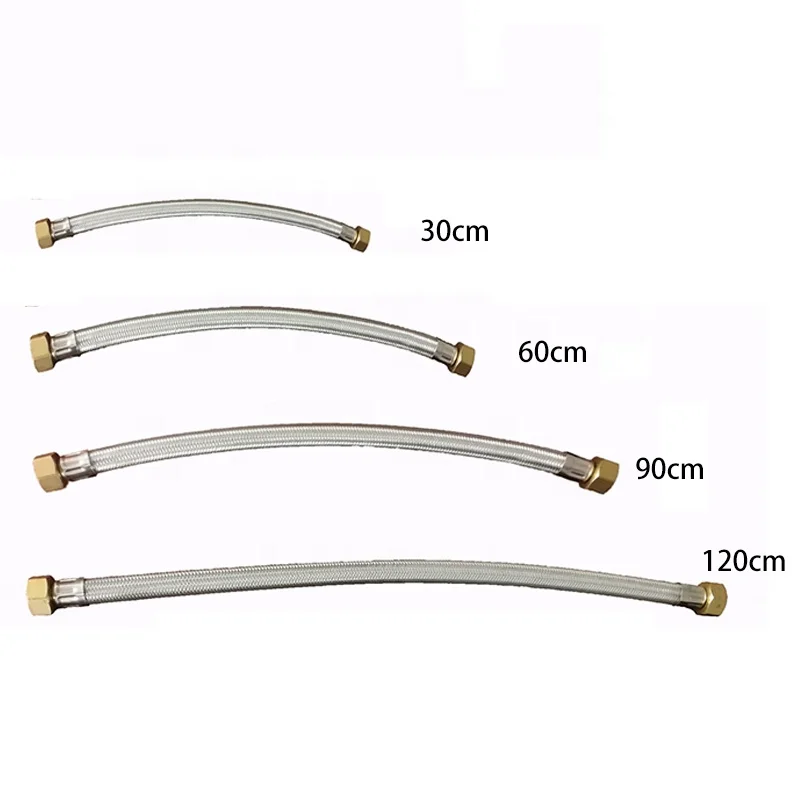

Introducing the Weiyue OEM/ODM Custom Made Brass Forging Machining Parts, designed to meet the exact needs of your industry with precision and reliability. These parts are crafted using high-quality brass material, known for its excellent strength, durability, and resistance to corrosion. With advanced forging and CNC machining technology, Weiyue ensures every piece meets strict quality standards and performs perfectly in its intended application

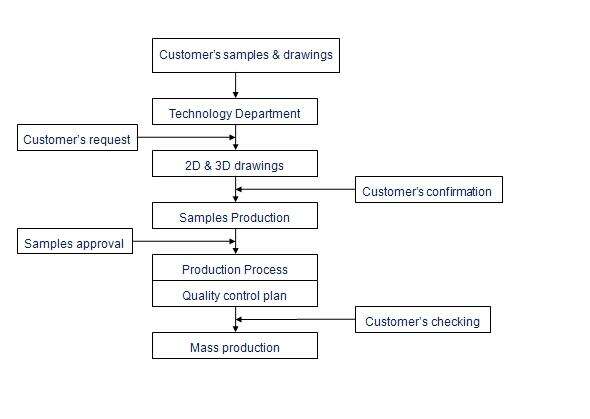

Weiyue specializes in OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, offering customized solutions tailored to your specific requirements. Whether you need a simple brass component or a complex machined part, Weiyue provides flexibility in design and manufacturing, ensuring your parts fit perfectly and function smoothly. The company works closely with you from the initial concept to the final product, making adjustments as needed to deliver parts that match your exact specifications

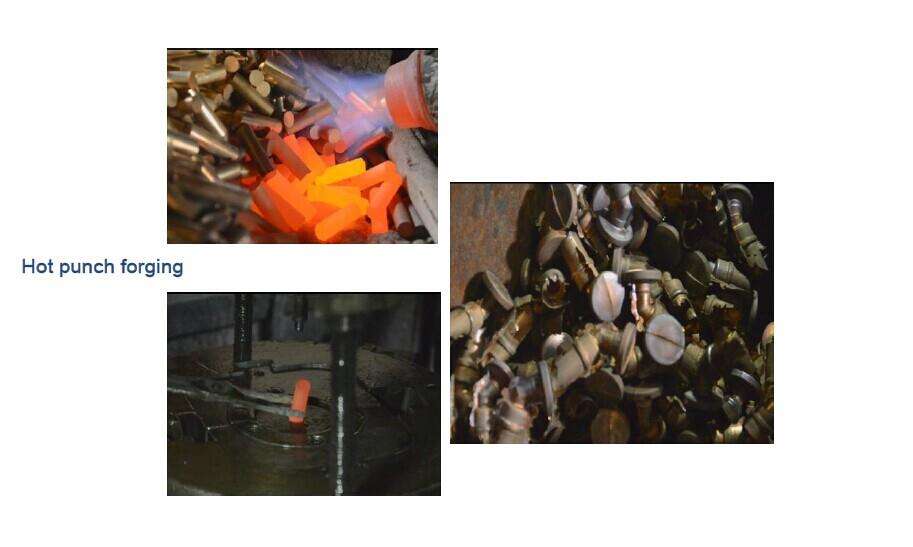

The forging process used by Weiyue enhances the strength and durability of the brass parts by shaping the metal under high pressure. This process refines the grain structure of the brass, producing parts that are tougher and more reliable than those made by other methods. Following forging, advanced CNC (Computer Numerical Control) machining is applied to achieve high precision and detailed features. CNC machining allows for complex shapes and fine tolerances, ensuring each part is consistent and accurate

Weiyue’s brass forging and CNC machining parts are widely used across various industries including automotive, electronics, plumbing, and industrial machinery. Brass is chosen for its excellent electrical conductivity and resistance to rust and tarnish, making these parts particularly suitable for applications where durability and reliability are crucial

Additionally, Weiyue offers fast turnaround times and competitive pricing without compromising on quality. Their experienced engineering team supports every project by providing expert advice and technical support to help optimize your products. Whether you have a prototype or require mass production, Weiyue’s custom brass machining services can scale to meet your needs

Weiyue’s OEM/ODM Custom Made Brass Forging Machining Parts combine high-quality brass material, advanced forging techniques, and precise CNC machining to deliver durable, reliable, and accurate parts. With a commitment to customization, quality, and customer service, Weiyue is a trusted partner for businesses looking for expert brass forging and machining solutions

| Material | Steel, Zinc, Alunumin, Brass. Stainless steel |

| Surface treatment | Nickel plating. Zinc plating, Chrome plating, Oxidation Anodization |

| Tolerance | +/-0.01mm or +/- 0.0004" |

| Thread Standard | NPT, BSPG, M, GHT, UN, NPSM, BSPT Tr, NPTF |

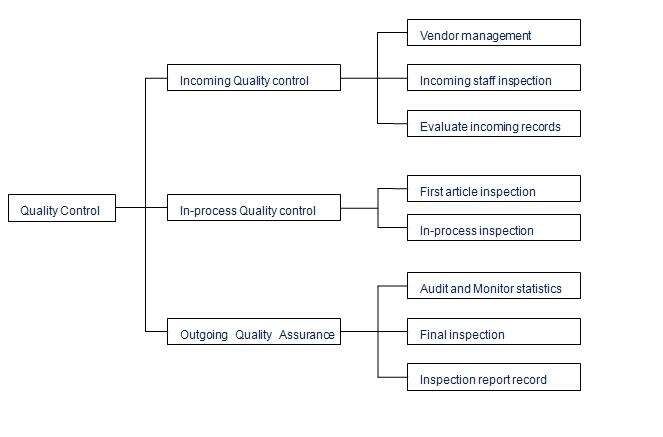

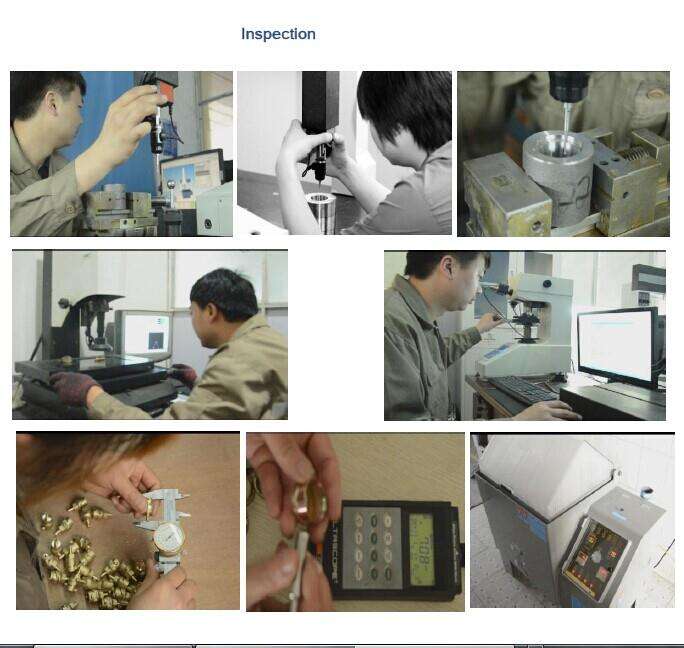

| Quality control | 100% inspection on critical dimensions |

| Inspection equipment | Three axis measuring machine for X. Y. Z. Projection meter |

| Production output | 500.000 pieces/ month |

| Productin range | Part ID from 2-500mm with tolerance +/-0.01mm |

| Experience | 12 years of professional OEM service |

| Supply chain process | PPAP |

| Ability | To develop hundreds of new parts annually |

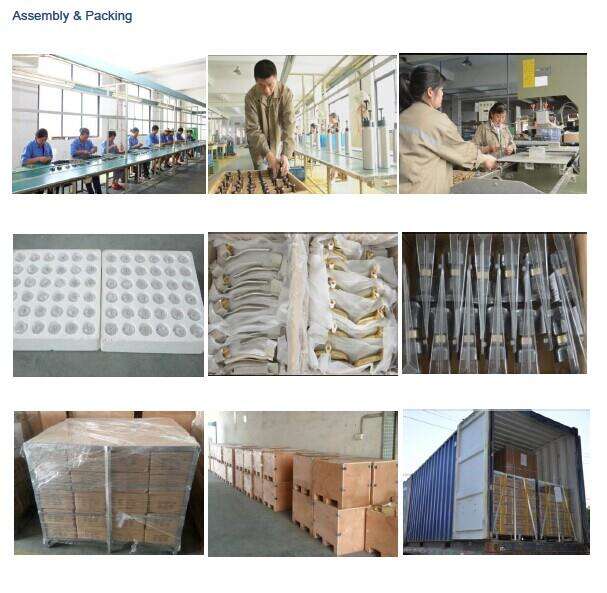

| Packaging | Standard export carton with palletized |

| Lead time | 35 days regularly |

| Term of Payment | T/T. L/C or Customer's request |

Fule

Equipments

PRODUCTION EQUIPMENT |

TYPE |

QTY |

AVAILABLE SIZE |

TOLERANCE CONTROL |

AVAILABLE MATERIAL |

CNC lathe |

Turning |

120 SETS |

MAX OD 120mm |

Min +/-0.01mm |

Brass, carbon steel, S. S, zinc, AL |

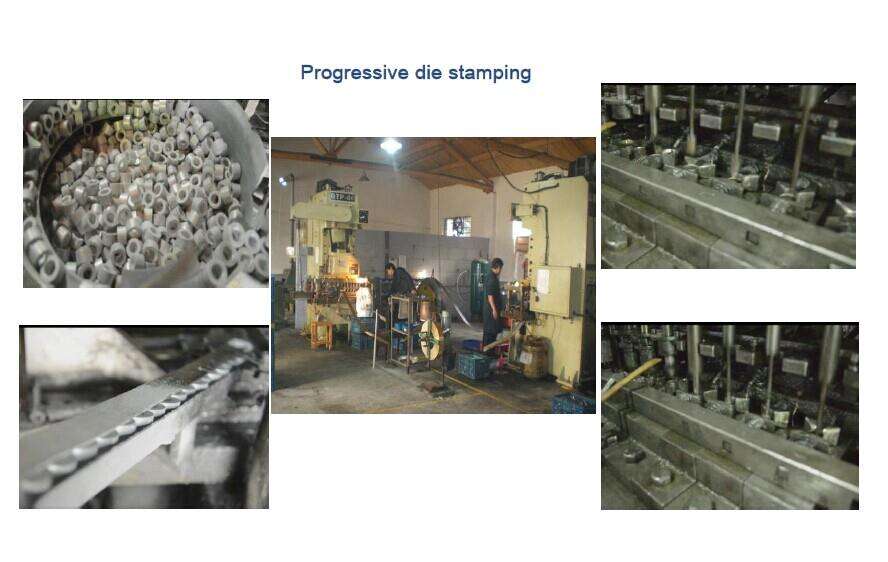

Punch |

Hot forging |

32 SETS |

60-80 tons |

Normal +/-0.05mm |

Brass, steel, S. S |

Cold forging |

15 to 100 tons |

Normal +/-0.05mm |

Brass, steel, S. S |

||

Hydraulic press machine |

Hot & cold pressing |

2 SETS |

315 tons & 500 tons |

Min +/-0.02mm |

Brass, steel, SS, AL |

Rolling machine |

Threading and diamond rolling |

2 SETS |

MAX OD 25MM |

Normal +/-0.05mm |

Brass, steel, S. S, Zinc |

Annealing machine |

Band turning |

2 LINES |

6m long |

100-800°C |

Brass, steel, AL |

Quality control

Order Flow

Products

Major advantages

1, 120 SET OF CNC machines for high output with quick delivery

2, Skilled and rich experienced staff. We manufacture over parts over 20.000.000pieces per year

3, Always Stable quality control.we can guarantee any single parts must at least 5 inspection process before delivery

4, Most Economic production process for cost saving

5, Material recycle scheme for cost reduction

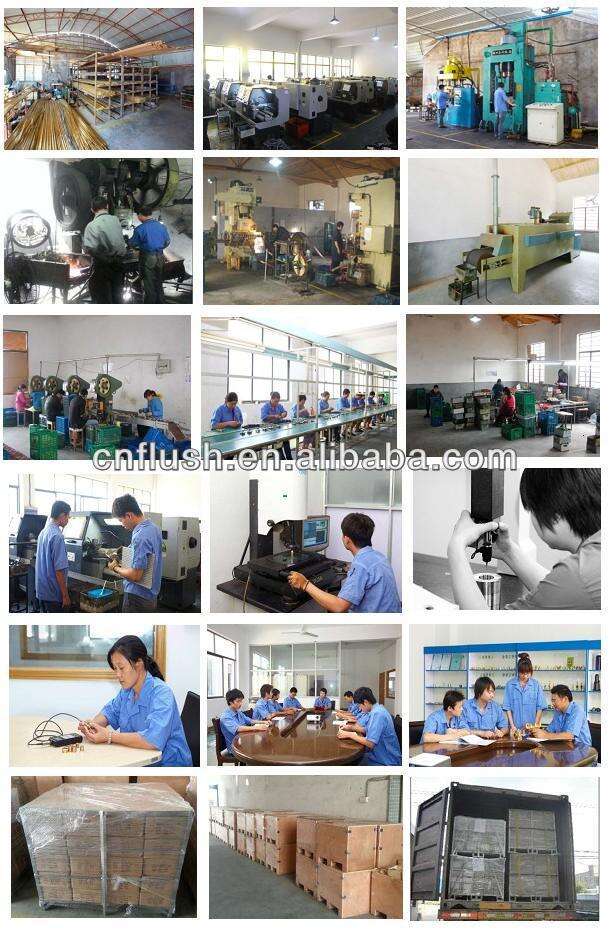

Production

Cixi Weiyue Metal Product Co., Ltd Former:Cixi Fule Flooding Equipment Co,. Ltd. production facility

All our products are manufactured under ISO9001:2015 certified factory, which have four floors of 6,400 square meters. Equipped with over 120 sets of CNC and punching machines, 100 sets of instrument lathes, 2 sets of hydraulic press, those have a monthly capacity of 3,000,000 units, to match your volume orders

Quality Control

All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard, to make sure that only quality parts leave our plant

Weiyue always focus on to reach client's demanding and satisfaction. 19 years of professional metal works metals fabrication company metalworking machinery metalworking metric bolts metric fasteners metric pipe fittings milling machine tools

1. Where is your location

We are located in Ningbo City of China and are closed to Ningbo port It takes 2 hours by car

2. Which countries do you export to

North American, European, and Asia

3. What proportion of your goods are exported

100% of our production are exported to all over the world

4. How long does it take to receive samples

A) Made from bar stock within 2 weeks

B) Made by dies usually 4-8 weeks

5. Why you limited the customer EAU purchase amount

We are the factory 100% produce the parts by ourselves to control the best quality, it cause the capacity limited